Key Takeaways

- Thread milling utilizes a helical cutting path, providing the flexibility to accurately control thread dimensions and is highly efficient for creating internal and external threads in diverse material types.

- CNC is important for thread milling because it allows extremely precise movements which provide better consistency, repeatability, and quality of threads.

- In contrast to tapping, thread milling produces less cutting force, eliminates the danger of tool breakage and enables threads to be milled in difficult or hard materials.

- An appropriate tooling selection, from single-profile to multi-profile mills, is necessary for producing the desired thread geometry and fine-tuning the process for application or material-specific requirements.

- Material properties have a huge impact on tool selection and machining parameters, so it’s important to pair your threading method and cutting tools properly with your workpiece for best results.

- Using the correct coolant strategy controls heat generation and chip evacuation, which preserves tool life and thread quality — particularly when threading at high speeds or on materials requiring precision.

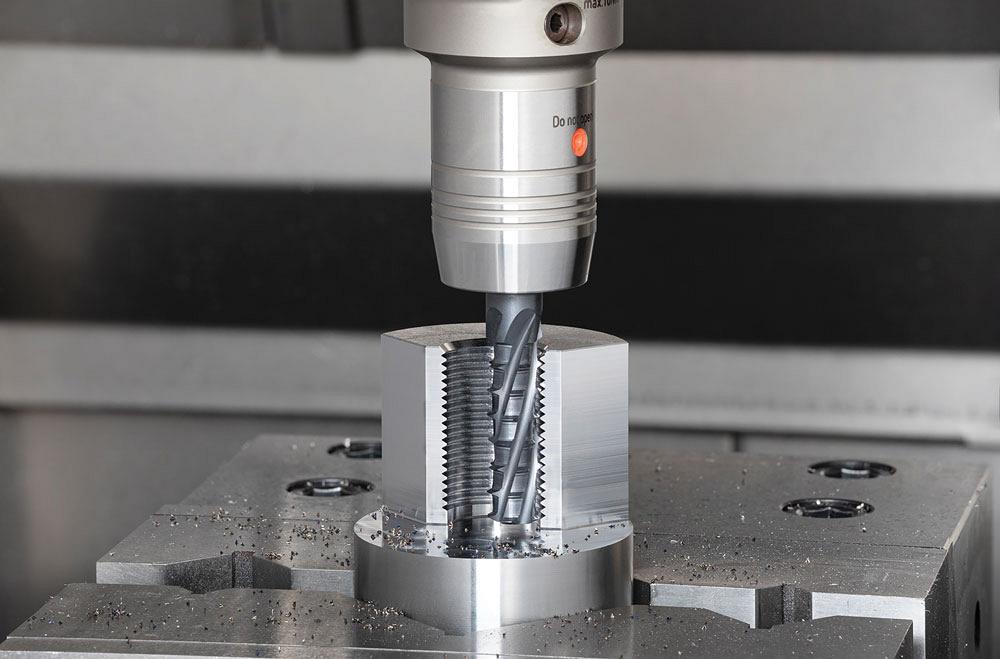

Thread milling is a process that employs a rotating tool to mill threads in a hole or on a surface. With thread milling, you have superior control over thread quality and size, as the tool is moved in exact trajectories by a CNC machine.

Shops tend to use thread milling for hard metals or hard work, since the technique applies less stress to the part than tapping. One tool can cut different thread sizes if the pitch matches, which reduces tool changes.

Thread milling allows you to create left- and right-hand threads using the same tool. In the following segment, the post will unravel how thread milling works and why it’s a robust choice for modern machining.

What is Thread Milling?

Thread milling is the process of cutting screw threads using an effective thread mill cutting tool on a milling machine. Unlike tapping, which drives or carves out a thread linearly, thread milling employs a tool that spirals along the cut, allowing for greater precision and versatility. This method is ideal for producing various threaded holes and accommodates different thread tolerances.

1. The Core Mechanics

Thread milling involves the use of a rotating tool — the thread mill — to generate threads in a workpiece. The thread mill is not a tap. A tap cuts only one thread size and form. A thread mill, if the pitch is correct, can cut many threads of different diameters so long as the tool can fit inside the hole.

For instance, a 16-pitch full-profile thread mill can mill any 16-pitch thread, metric or unified, if the hole is big enough. This provides machinists with greater flexibility and reduces the tooling required.

Thread mills come in a few varieties. The single-form cutter, which has only one row of teeth, is ideal for deep or difficult to access holes. Tri-form and multi-form cutters have more rows of teeth, so they cut the thread faster and with less passes. These options allow users to select the cutter that fits their task, be it for fine threads, coarse ones, or hard metals.

2. The Helical Path

The primary motion in thread milling is the helical motion. The thread mill rotates rapidly as it travels in a circle inside the hole. Simultaneously, the tool moves either up or down by the precise thread pitch every time it completes a revolution. It’s this shape that makes the thread.

This helical tool path keeps the cutting forces low and allows the tool to cut cleanly. It minimizes the chance of tool breakage, as in tapping, particularly in hard metals or small holes.

For blind holes, where the hole doesn’t go entirely through, thread milling makes it possible to get a full thread almost to the bottom, which tapping can’t.

3. The CNC Role

CNC machines are a must for modern thread milling. This requires precise control of the thread mill’s path, speed, and feedrate. The feedrate needs to be equal to the pitch of the thread; otherwise, the threads will be oversize or rough.

With CNC, you can program the mill for just about any thread type. It can cut metric or unified threads, Acme threads, or special forms. The operator can adjust the class of fit or thread angle in the code, so the same tool can produce different threads in a single setup.

This is a timesaver and productivity enhancer, particularly in the custom or low volume work.

4. Versus Tapping

Thread milling excels in versatility. One tool can thread many sizes or types, whereas taps require a new tool for each thread. Thread mills are able to work on harder materials and create threads in blind holes with less chance of snapping.

Tapping is quicker for big runs of the same thread, but it’s restricted in what threads it’ll cut and more prone to snap in tough metals.

Thread milling can generate metric, UN, or Acme threads with a single tool.

Why Choose This Method?

Thread milling remains a contemporary option for anyone seeking reliable, high-quality threads. For shops and engineers, this thread milling operation provides tangible advantages over tapping or thread turning, particularly in terms of speed, tool life, and part quality. Numerous international businesses have moved to thread milling to stay ahead of escalating requirements for precision and speed.

Thread milling reduces machining time in an obvious, quantifiable fashion. Unlike thread turning, which can take multiple passes, or tapping, which frequently demands slow, careful tool changes, the thread mill cutting tool utilizes a single tool path. The tool advances in a helix, creating the thread in a single stroke. That translates to less downtime and fewer tool changes.

For example in production lines producing high volume runs of metric bolts, migrating to thread milling reduces total cycle time by a few seconds per part. That might seem tiny, but over a thousand components, the savings really pile up.

The technique extends the life of your machine spindle. Other methods such as tapping require the spindle to decelerate and reverse for each thread, causing mechanical wear. Thread milling keeps the spindle spinning this way, relieving the stress. Shops dealing with pricey machinery—be it aerospace or medical—often opt for thread milling to maintain their equipment and minimize expensive downtime.

Thread milling is notable for its low energy consumption. Because the spindle doesn’t have to stop and start for each reverse, less power is pulled, and the process remains smooth. This results in reduced operation costs and reduced heat accumulation.

That’s a huge factor in environments with servers grinding 24/7 and power expenses. Thread milling provides higher thread quality as well. This method blows chips free as it cuts, rather than having them trapped in the hole. That means cleaner threads, less rejects and less post-processing.

When threading vacuum fittings or medical implants, for example, users tend to encounter a more consistent finish and less trouble with chip clogging. Thread milling earns its worth in hard labor. It compliments hardened steel up to HRC 65, titanium and other difficult-to-machine materials.

This would unlock potential in sectors that require rugged threads, like automotive or energy. Conventional tapping often flounders or fails in these materials. For blind holes, thread milling provides a complete thread profile from top to bottom.

With tapping, you usually have to bore the hole deeper to achieve the same effect, squandering both material and time. Thread milling’s control means it can be used for very precise features, assisting in compact designs where space is a premium.

Thin-walled parts, such as those found in electronics or lightweight structures, thrive from thread milling’s low cutting force. It applies less stress to the workpiece, so parts don’t bend or distort, and the finished thread remains true to size.

Finally, the technique can provide a burr-free thread entrance, which is particularly true with the right thread milling cutter. This cuts hand-finishing, saves labor, and results in a more professional product, whether it’s aerospace fasteners or precision lab gear.

Tooling for Precision

Thread milling is a dependable way to make threads if you require precision or a quality surface finish. It’s the go-to option for producing parts such as medical implants or custom fasteners, where thread quality is critical.

Contemporary CNC machines unlock thread milling’s full advantages, allowing operators to customize tool paths, spindle speeds, and feed rates for every application. Less tool wear, longer tool life, smoother cuts — even in tough or tricky materials.

Single-Profile

Single-profile thread mills machine a single thread at a time, following the helical contour of the thread shape. It provides unparalleled flexibility, since the very same tool can cut internal or external threads, right- or left-handed, or even custom thread pitches.

With a one-profile cutter, users do minor adjustments to CNC programs to customize the thread measurements, reducing tooling expense and inventory requirements. For multi-thread mix industries such as aerospace, these all-encompassing single-profile tools are prized for their versatility.

These tools are popular in precision machining of hard metals or engineering plastics as the smaller contact area implies smaller cutting forces. This yields less risk of part distortion and superior burr-free finishes.

Single-profile cutters are a natural fit for sophisticated CNC controls, enabling ultra-precise work in high-stakes fields such as medical device production.

Multi-Profile

Multi-profile thread mills have a number of rows of cutting teeth, therefore they can create an entire thread in a single pass. This design accelerates production, making it ideal for high volume runs or where cycle time is king.

Multi-profile cutters really shine in automated lines, where each second saved equates to more production. While quicker, these tools sacrifice flexibility—each tool corresponds to a particular thread pitch and shape.

They’re most effective in environments where a very particular thread type must be repeated over and over, like in the manufacturing of automotive parts. Tool wear can be tamed with prudent speed control, particularly when cutting heat-treated alloys.

CNC machines assist in maintaining precision, even as the tooling wears. For big production, the quicker cycle time and consistent thread form of multi-profile mills reduce expenses and increase output.

Most shops maintain both single- and multi-profile tools, selecting the appropriate one according to the combination of parts and finishes.

Helical Flute

Helical flute thread mills use angled cutting edges to slice through material, which brings two main benefits: reduced cutting force and smoother action. For jobs where chatter or vibration is an issue, these tools are the go-to.

High helix angles lift chips out of the cut, so the tool stays cooler and parts have a beautiful finish. In titanium or stainless, where the threads have to be just right, this type of fluting design keeps the work solid.

The shear cutting of helical designs is crucial when cutting threads in thin-walled or fragile components. Shops rely on helical flutes for medical and aerospace parts, where even the tiniest burrs can’t be tolerated.

The capability to run faster without sacrificing part quality translates to more efficient machine utilization and less time spent swapping tools.

Straight Flute

Straight flute thread mills have their teeth aligned with the axis. These are ideal for all-purpose threading in softer substrates such as aluminum or technical plastics.

They’re straightforward, cheaper and easy to install, so they’re a great choice for runs. In CNC shops, straight flute cutters are employed for threads where a high finish isn’t required.

Their simple form renders them less costly than other configurations.

Mastering the Process

To master thread milling, one must begin with the basics. It starts with understanding thread designations, which detail the shape, pitch, and size of the threads. These nomenclatures vary by system—metric threads are measured in millimeters, while UN threads are in inches. Classes of fit, like 6H for metric or 2B for UN, indicate how tight or loose the thread will be, influencing the selection of the right thread milling cutter and processing methods.

Understanding the principal thread types is essential. Metric threads feature a 60° flank, while UN threads are virtually the same. Acme threads, on the other hand, have a 29° angle and are flat on the crest. Choosing the appropriate form is crucial, as each type requires varying milling passes and suitable thread mill cutting tools.

To achieve high precision in thread milling operations, it is vital to monitor several factors. The thread pitch, or how far the thread travels from one to the next, must align with the design. An incorrect pitch means the part won’t fit or lock as required. Tool clearance is also critical—using a thread mill cutting tool that is too large can damage the part, while one that is too small may leave ragged threads.

Feed rate, or how quickly the tool travels, defines surface finish and impedes tool wear. For instance, hard materials such as tool steel or Inconel require slower feeds to prevent the cutter from fracturing. Milling titanium requires employing sharp cutters and an abundance of coolant to prevent heat generation.

Thread milling is very versatile. One tool can cut inside and outside threads, as well as right- and left-hand threads. It ranges across sizes, and by varying the tool path, you can cut M5 or M60 threads with the same tool. This versatility is handy in shops with lots of thread sizes, as it reduces the tool count.

The helix angle is something else to understand. It’s typically 15-30°. The correct angle maintains the tool’s motion in a gentle spiral, cutting the thread form. A mistaken angle can result in either a poor crevice fit or a rough finish.

One of the keys to successful thread milling is knowing which cutter to use. Single-form cutters are designed to cut one thread at a time, making them suitable for odd or custom pitches. Tri-form cutters can form multiple thread sections per pass, speeding up the process but requiring more careful setup. Multi-form cutters can complete the entire thread in a single pass and excel in volume production but are less adaptable to different thread tolerances.

Thread milling does work on difficult materials, which is a major advantage. I’ve threaded in tool steel >45 HRC, as well as titanium and Inconel. It’s slower but you end up with nice, clean, true threads where tapping would fail. This is crucial for aerospace and medical, where parts have to endure.

To succeed in thread milling, mastering the entire process is essential. You need to select the right thread milling tool for the material and thread shape, adjust the speed and feed accordingly, and inspect your initial threads for fit and dimension. Thoughtful preparation and regular monitoring are the keys to achieving success in this intricate machining approach.

Material Challenges

Thread milling has unique hurdles, mostly because the workpiece material can change the whole process. Many metals used in high-demand fields, like 718 Inconel, Haynes 25, Ti-6Al-4V, 455 stainless steel, and high-temp alloy steels, are tough to cut. These super alloys fight against the tool, so you need cutting edges made from carbide.

Carbide keeps the tool sharp longer, slows down wear, and lets you cut at higher speeds. In production, the goal is to keep the tool running and avoid downtime. If you use something softer than carbide, the tool will blunt or break fast, and you will waste time changing it out. In a real-world example, machining a deep thread in Ti-6Al-4V with a standard high-speed steel cutter often leads to tool snapping in a matter of minutes, while a carbide tool can last for several holes before needing replacement.

Add to that various thread forms and standards and you have another layer of challenge. Not all threads are created equal—even if they appear close. Metric threads possess a round root, whereas SAE threads are flat at the root. This bit alters the cutter’s movement and the final thread’s fit.

If you have a single thread mill for all pitches, the thread form might not be ideal. In specialty industries, such as aerospace or medical, this could imply a component doesn’t pass inspection. For these tasks, a cutter ground for the particular pitch is ideal. It works better but means you have to have more implements available and more foresight before you begin.

Dividing the cutting load among several teeth on the tool helps with hard materials. Some thread mills use a design where the first tooth roughs the material and the next ones finish the thread. This staggered work slows down wear on each cutting edge.

It lets you keep the same tool in place longer, which means fewer stops and more parts done per shift. For example, thread milling 455 stainless steel with a multi-tooth carbide mill can double or triple tool life versus a single tooth cutter.

Certain tasks require more than just the perfect cutter. Some materials spit hot or create hard chips that clog the hole. Internal coolant supply is key here. Coolant keeps the tool cool, washes chips out and ensures you get a full thread – all the way down to one pitch from the bottom of the hole.

Without coolant, you’re asking for tool breakage and crappy thread finish, particularly in deep or blind holes. The thread angle and form alter matters as well. Tress threads, which endure intense force in one direction, require particular attention.

The cutter profile, tool path, and even threading entry and exits all change to fit the thread profile. Sometimes, a 60° Double Angle Shank Cutter is just the ticket, particularly if you require razor-sharp thread crests in a difficult alloy.

The Coolant Strategy

Coolant strategy influences just about everything in thread milling. In thread milling, heat and friction can accumulate quickly. This can cause tool wear, poor surface finish, or even thread mistakes. Coolant helps prevent these issues. It cools the tool and work piece, reduces friction and assists in clearing chips from the cut. Good chip evacuation is crucial, because chips left in the groove can mar the threads or tool edge. The correct coolant selection and application can have a dramatic effect on thread finish and tool longevity.

Others machinists like to use high-pressure coolant. High pressure that washes chips out of the cutting zone, keeping the tool sharp and thread form clean. This is typical when dealing with hard-to-cut materials such as titanium or stainless steel. For these, chips can stick in the thread path and chatter or break. High pressure coolant not only keeps the area clean but cools fast, which can prevent the tool from overheating and losing its edge.

For instance, in aerospace part shops, high-pressure coolant is virtually always used for thread milling on hard alloys to prevent expensive tool wear and rework.

Some other machinists opt for a light or even dry cut. This is particularly common when threading in soft or easy to machine materials, or when dry machining is required for environmental or process reasons. Certain plastics, for instance, respond poorly to specific coolants and can expand or erode. Here, the chips might not adhere as much and dry can break things up easier.

For dry cutting, the tool geometry and speed need to be selected carefully to keep heat and wear manageable. For certain aluminum alloys, a light mist or air blast can replace liquid coolant, just to push chips clear.

The kind of coolant counts, as well. Water based coolants are prevalent as they cool effectively and can be diluted for numerous tasks. Oil-based coolants are chosen for hard cuts or when surface finish is a priority. There are even synthetic coolants for specialty applications, such as titanium machining. It depends on both the workpiece and the process.

For instance, when thread milling medical parts from titanium, a synthetic coolant will drop chemical reactions and keep the tool from sticking. In a high-volume automotive plant, a rust-inhibited water-based coolant might be employed for steel parts to keep both tool and machine clean.

A sound coolant strategy can enhance surface finish, reduce tool wear and increase productivity. Surface finish is improved with chip clearance and tool wear decreases with low friction. Other machinists mention that coolant helps reduce thread errors, such as pitch mismatches or out-of-shape forms, since the tool operates cooler and more stable.

Yet the strategy may need to vary by what’s being cut, tool shape or thread specs. If the job switches from steel to plastic, the coolant might have to switch as well. Occasionally, an air-coolant mixture is deployed for gnarly work–air removes chips and coolant chills the cut. This combo works especially well in deep holes or blind threads, where chips can accumulate.

Conclusion

Thread milling provides sharp, clean threads with minimal chance of breakage. You can change tools quickly, thread multiple sizes with a single tool and solve common shop headaches. Machines go smooth if you set speeds and feeds right. Hard metals and soft plastics both require TLC, but a solid strategy and appropriate coolant make you the champion. Thread milling shops experience less scrap and get perfect threads consistently. These real-world gains manifest themselves in saved hours and improved parts. For operators looking to expand their expertise or maximize production, thread milling is where it’s at. For a deeper dive or to contribute your own shop tips, join the conversation in the comments or read our next guide.

Frequently Asked Questions

What is thread milling?

Thread milling is a machining approach where an effective thread mill cutting tool rotates to cut threads in a hole, following a helical toolpath for internal and external threads.

What are the benefits of thread milling over tapping?

Thread milling is more flexible, yields excellent quality threads, minimizes breakage risk and is compatible with hard or difficult materials.

What types of tools are used in thread milling?

Thread milling can employ an effective thread mill cutting tool, multi-tooth cutters, single-points, or indexable inserts — all crafted for accuracy and different thread tolerances.

Can thread milling be used on all materials?

Yep, thread milling operations work on metals, plastics, and composites. The right thread milling cutter and cutting parameters must be congruent with the material for optimal outcomes.

Why is coolant important in thread milling?

Coolant cools, flushes chips, and extends the life of the thread milling cutting tool, contributing to cleaner threads and avoiding workpiece damage.

Is thread milling suitable for blind holes?

Thread milling is perfect for blind holes. It enables accurate depth control and prevents problems such as tap breakage at the hole bottom.

How do I ensure accuracy in thread milling?

Employ quality tooling, such as an effective thread mill cutting tool, appropriate machine parameters, and adequate coolant for optimal precision and stability.