Key Takeaways

- CNC technology uses computers to control machine tools, delivering high precision and automation across American manufacturing, from aerospace to automotive sectors.

- Understanding how to do programming and digital design is very important. Using CAD and CAM software as part of the CNC process guarantees the precise translation of design concepts into physical components, improving communication, streamlining workflow and cutting down on design errors.

- CNC machines provide greater consistency and production speeds than manual processes. In addition, they reduce the susceptibility to human error, making them perfect for use in both large-scale and custom projects.

- CNC operations such as milling, turning, cutting and grinding provide a high level of versatility. They allow complex, high-precision parts to be made from metals, plastics, and other materials that are now standard in U.S. industries.

- Regular maintenance, proper setup and operator training are key to both efficiency and safety. In commercial manufacturing environments, they optimize CNC machine productivity, guard against misuse, and prolong machine life.

- For manufacturers in the United States—large and small, new and old—to remain competitive, they must adopt the latest innovations, including AI and robotics. As CNC technology evolves, it will create new ways to change production processes.

CNC is an acronym for computer numerical control. This allows computers to control how machines cut, mill, or otherwise shape metal, wood, and plastic in high-tech shops and factories all over the U.S.

Makers in cities like San Francisco utilize CNC to fabricate automotive components, surgical instruments and even sculptures. CNC tools provide quick, precision cuts and allow for the production of repetition of the same item.

As a final example, we’ll take a look at how CNC functions in actual world careers.

What Exactly Is CNC Technology?

CNC technology stands for Computer Numerical Control, a method where computers run machines to cut, drill, mill, or shape parts. That’s the name of the game in this process, where high precision and automation go hand-in-hand.

CNC machines are incredible at performing operations that require close tolerances and performing the action repeatedly, identically, over and over again. That’s a huge benefit for manufacturing, where speed, precision and repeatability are of the essence.

With CNC, it’s quicker to manufacture complex parts, produce less waste, and maintain consistent quality. Today, aerospace, auto manufacturing, and medical device plants are just a few examples of industries that depend on CNC tech. It allows them to increase production while continuing to meet rigorous specifications.

The “Computer Numerical Control” Meaning

The phrase “Computer Numerical Control” splits into three fundamental parts. The “computer” part means the electronic brain that controls everything.

Control” means that the actions of the machine are controlled by a computer. Control” means providing very detailed direction for every step. The computer then interprets these digital commands, transforming CAD designs into actual movements.

This is where the programming comes in; the programming is what tells the machine how deep to cut or where to move. CNC evolved from earlier numerical control systems that used punch cards as early as the 1940s.

How CNC Machines Actually Operate

Each CNC machine consists of a control unit, motors, and feedback systems combined to control the machine’s movement. Operators begin with a CAD file, from which CAM software translates the design into machine code.

The machine then reads these instructions, moves its various parts, and carves, mills or drills the material accordingly. Feedback systems monitor each step, ensuring there are no mistakes and maintaining the whole process in register.

This CGI technology enables CNC machines to operate on metals, plastics and other materials performing tasks such as milling or drilling effortlessly.

CNC Versus Traditional Manual Methods

Additionally, CNC machining is much quicker and more uniform compared to traditional manual work. It can do the same thing over and over again a million times with no decrease in quality.

Operators no longer require years of training—an understanding of basic machining skills and CNC programming is all it takes. CNC reduces chances of human error, resulting in safer and more reliable production.

A Brief Look: CNC’s Origins

In fact, CNC technology really got its start back in 1949 with punch-card operated machines. As the years went by, computers became the dominant machines and with the introduction of technologies such as AI and sensors, CNC became even more intelligent.

The move from manual to automated work transformed factory operations overall, allowing them to be more nimble and efficient.

The CNC Workflow: Idea to Part

The CNC workflow is a perfectly orchestrated chain of events. It takes a design idea and turns it into a production-ready part. Each step requires collaboration between designers and engineering professionals. This combination of talents is what makes for a consistently low error rate and high quality.

In Sanand other U.S. Cities across the country, small boutiques and big box stores are raising their stakes. Now, they are able to produce bespoke parts for technology, health care, and aerospace!

The main stages in the CNC workflow are:

- Digital design (CAD)

- Design conversion (CAM)

- Machine setup

- Monitoring and production

Digital Design: CAD’s Crucial Role

Digital Design CAD’s Crucial Role CAD software is the centerpiece of the digital design workflow. Designing with CAD allows teams to design parts with precise dimensions and geometries. This allows them to test fits and identify problems up front.

CAD allows all of the stakeholders to view the part as a 3D model. Even before the first piece of metal is cut, CAD files undergo review and repair. These files quickly become CNC programs. That early attention to detail reduces errors and rework on the shop floor.

From Design to Instructions: CAM

CAM From here, CAM (computer-aided manufacturing) software takes over, receiving CAD files and writing the step-by-step code the CNC machine will follow. CAM can select the most efficient tool paths and speeds to accomplish the job, reducing time and increasing accuracy.

Tool choice and setup in CAM is crucial, as this step determines how closely the finished part will resemble the design. CAM programs load right into CNC machines, which helps keep the entire process connected.

Machine Setup: Precision Starts Here

Machine Setup: Precision Starts Here Setting up a CNC machine begins with verifying the part program, tool, and material. Operators carefully set up work, tool length and cutter radius offsets. Skill in this case is the proper fit and close tolerances.

Fixturing and calibration are important, as improper setup can destroy parts. The first one won’t be perfect, so steps should be taken to check often.

Watching the Machine Create

Watching the Machine Create CNC operators closely monitor the machine’s progress. They monitor feedback, inspect cuts, and preempt issues before they incur time or material waste.

With each run, the data received helps inform future jobs, thus turning each part into a building block for more favorable outcomes.

Key CNC Operations Demystified

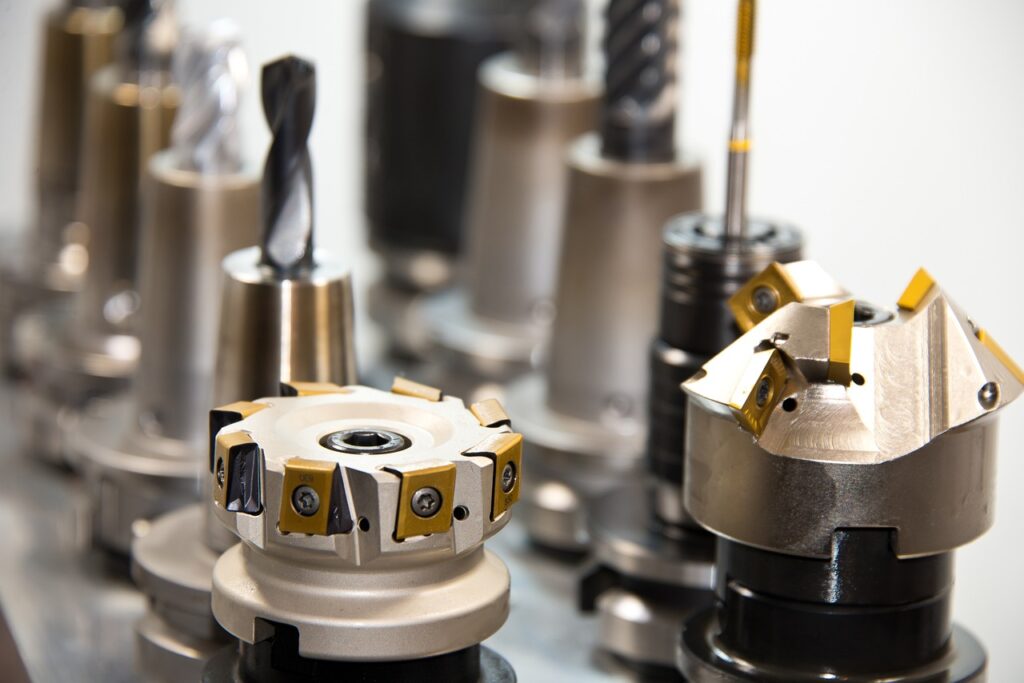

CNC machines perform some of the most fundamental operations that add geometry and purpose to today’s components. These operations let shops work with a mix of metals and plastics, from aluminum and brass to titanium and high-performance polymers.

All three techniques employ computerized control of cutting tools to remove material, create intricate features, or shape a part’s surface with precision. It’s imperative that tech professionals and engineers understand these steps. It’s just as important for generating clean code, selecting appropriate tools, and keeping tight tolerances.

|

Operation |

Main Application |

Typical Materials |

|---|---|---|

|

Milling |

Complex 3D features, slots |

Aluminum, steel, plastic |

|

Turning |

Cylindrical parts, shafts |

Brass, titanium, stainless |

|

Cutting |

Sheet profiles, intricate cuts |

Steel, aluminum, composites |

|

Drilling |

Holes, threads |

Steel, aluminum, polymers |

|

Grinding |

Ultra-smooth finishes |

Hardened steel, ceramics |

|

EDM |

Hard, complex shapes |

Carbides, tool steels |

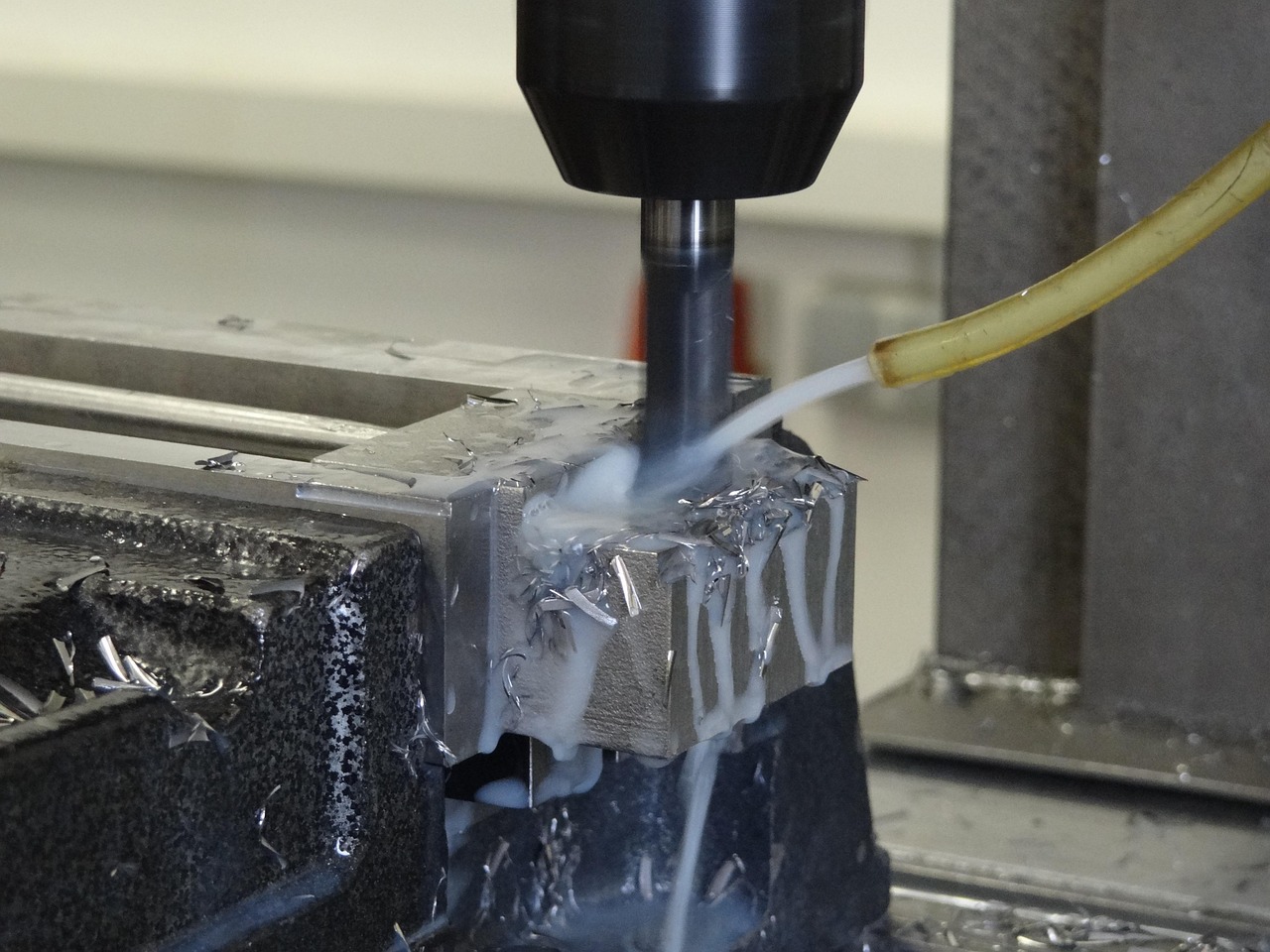

1. Milling: Shaping with Rotating Tools

Milling is the most prevalent operation in CNC machining. The process involves a spinning tool—such as an end mill or ball cutter—removing material from a solid block.

This allows programmers to create keyways, dovetails, pockets, or even 3D shapes. Compared to manual milling, CNC provides highly repeatable moves at high speed and with tight tolerances (as close as ±0.025 mm).

Benefits Five-axis milling allows the end mill to reach corners and unusual angles in one setup.

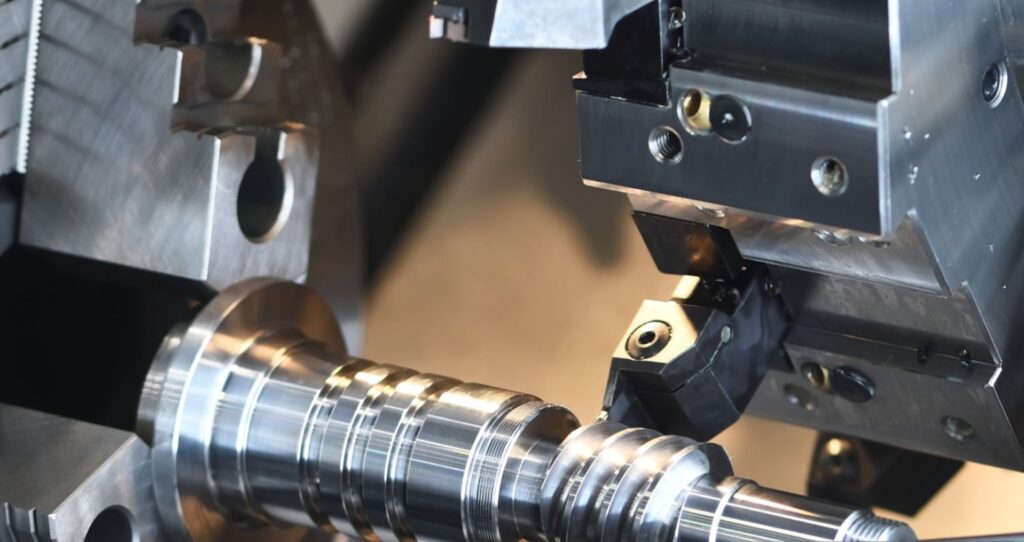

2. Turning: Crafting on a Lathe

Turning process is used to turn down a spinning rod or tube with a fixed tool. It is the default choice for any kind of cylindrical part such as bushings or axles.

CNC lathes ensure the cuts are consistent and exact, allowing for easy repetition of runs or adjustments to create custom work.

3. Cutting: Plasma, Laser, Waterjet

CNC cutting operations utilize a variety of technologies to cut sheets and plates of material, or shaped parts. Plasma is really the best option for cutting thicker steels.

Laser really excels in creating sharp, clean details on small, thin sheets, whereas waterjet can cut just about anything—including ceramic or composites—without any heat involved. Each has its tradeoffs for speed, edge smoothness, and cost.

4. Drilling and Threading Holes

Drilling creates holes, and taps or thread mills are used to create internal threads. CNC maintains depth and location precision, ensuring each hole meets the spec.

Makers especially use this to create bolt holes in 3D printed housings, or threaded inserts in electronics.

5. Grinding: For Ultra-Fine Finishes

Grinding employs a wheel made of abrasive particles to remove material from a part for smoothing or sizing purposes. CNC grinders are used to achieve extremely tight tolerances on parts such as hydraulic shafts or molds.

They provide ultra-fine finishes that cutting tools just can’t reach.

6. Electrical Discharge Machining (EDM)

EDM spark discharge between an electrode and the work. It erodes intricate or fragile geometries that would be difficult to cut with a standard tool.

EDM is often used to create dies, molds, or to remove a broken bolt.

Machines, Materials & Real-World Uses

CNC, or computer numerical control, is at the very heart of today’s advanced manufacturing. It allows shops in San Francisco, and all other U.S. Shops, to produce parts rapidly and to very precise specifications. These machines are highly diverse, each uniquely suited to specific tasks.

How you choose to select one frequently determines the price tag, the amount of delay, and the final product.

Exploring Different CNC Machine Types

The three primary types are mills, lathes, and routers. Mills remove material from complicated shapes, frequently able to machine five of six sides of a part without resetting. Lathes are CNC machines that spin workpieces to shape them, best suited for round parts like gears or engine components.

Routers, which are lighter and faster machines, are suited to cutting wood, plastics, or more malleable metals. Advanced prototypes, such as 5-axis models, take that foundation and extend it further, introducing additional axes of movement and rotation to the creation process.

This allows shops to create geometries that were once impossible. The type you choose will largely depend on the size, shape, and detail level of your desired outcome.

Common Materials CNC Can Tackle

- Steel

- Aluminum

- Titanium

- Brass

- Plastics (like ABS, nylon, polycarbonate)

- Composites

For metals, you require heavy-duty machines and specific tools with sharp bits. Plastics require carefully calibrated feeds to prevent melting. Finding that correct match translates into less rework and greater success.

Each material has an impact on the strength, weight, and toughness of the finished part.

Industries Transformed by CNC

Auto, aerospace, health care—and yes, even agriculture—depend on it. Imagine they’re the frames of cars, engines of airplanes, instruments of surgery or sheers in your garden. Hospitals rely on CNC for implants and orthotics as its repeatable accuracy makes it an ideal choice for these productions.

Shops monitor their machines in real time, using data to reduce waste and increase production.

Everyday Items Made with CNC

CNC machining allows manufacturers to maintain tight quality control and produce customized one-off components, such as cell phones, laptops, bicycle components, and even bespoke footwear, to meet specialized requirements.

CNC: Advantages, Limits & What’s Next

CNC, or Computer Numerical Control, represents a major revolution in the manufacturing process. With CNC machining, you have a method to produce parts that’s incredibly fast yet extremely dependable. Understanding CNC machine programming helps you avoid common pitfalls and get the most out of CNC manufacturing. These advantages and disadvantages dictate shop processes, project planning, and worker skillsets.

|

Advantages |

Disadvantages |

|---|---|

|

High precision (up to ±0.0025mm) |

High upfront costs (machines, tools, software) |

|

Consistent part quality |

Needs skilled programming for complex jobs |

|

Runs long hours with little oversight |

Limited by machine bed size |

|

Low user error in automated runs |

Slow to change designs |

|

Saves and repeats designs easily |

Ongoing maintenance required |

Why CNC Often Wins Out

CNC machining provides a tremendous advantage compared to manual machining processes. For production runs, shops can produce hundreds of identical parts with minimal hassle. The cool thing about these CNC machine tools is that they consistently operate within the same tight specs over and over.

This increase in speed and efficiency in the CNC manufacturing process results in a significant reduction in waste and increased profit margins, particularly for larger, bulk orders. CNC setups are easier to replicate for new work with minimal retooling, allowing fabricators to be more agile and pivot to meet demands as they arise.

By keeping electronic files, a shop can reproduce previously manufactured CNC workpieces without any additional setup.

Understanding CNC’s Practical Challenges

CNC is not plug-and-play. Each job requires setup for the specific job, and the first one is quite time-consuming. Purchase and maintenance expenses are steep, plus bed size limits large parts.

Elaborate geometries require advanced programming mastery, and ultimately even the most advanced machines can stray from spec without frequent calibrations. It’s the skilled operators who spot small problems early and help get lines moving.

The Future: AI, Robotics in CNC

New technology continues to reshape the landscape of CNC. AI and automated robots are taking care of rudimentary tasks, reducing waste, and maintaining production lines around the clock.

Today, thanks to IoT, machines not only communicate with each other, they autonomously organize and pack parts. This trend will undoubtedly continue. Factories of the future could operate with even fewer humans, and CNC could get even more intelligent.

Safety Essentials in CNC Environments

Safety is first and foremost around CNC. Shops require strict regulations, personal protective equipment including goggles and gloves, and concise training informational.

Preventive practices such as ensuring guards are in place and removing chips help reduce the chances of cuts or jams. Appropriate training empowers workers to identify hazards before they become issues.

Maintaining Your CNC Investment

Maintaining your CNC investment requires a delicate balance. Shops should maintain service logs, machine cleanliness, and routine maintenance checks.

Preventive measures, such as daily oiling and weekly calibrating of the machines can vastly increase the lives of the machines. When problems arise, an easy solution gets operations back in order.

FERR is a professional CNC-Machining manufacturer, which can realize rich customization of materials and types for various industries. And we provide professional 1v1 customization service, welcome to consult our 24h customer service.

Conclusion

CNC is short for Computer Numerical Control. Shops in every state in the U.S. Are using it every day. The industry depends on it to precision cut steel for car frames, stamp plastic for electronics and machine wood for furniture. CNC allows people to produce the same complex part repeatedly, regardless of the size of the job. What’s the actual value? Machines replace the heavy lifting with quickness and precision. This means people waste less time on errors and more time creating concepts! Shops in San Francisco or Detroit need CNC to remain competitive. Make your first steps in CNC by jumping into the fundamentals! Increase your shop’s productivity by testing one easy project. Always remain inquisitive, keep questioning, and continue developing your talents.

Frequently Asked Questions

What does CNC stand for?

What does CNC stand for? It is a technology that employs computers in cnc machine programming to control machine tools for the highly accurate manufacturing processes of complex parts.

How does CNC improve manufacturing?

By using CNC machining technology, manufacturers can significantly enhance accuracy, speed, and consistency in the machining process. This advanced CNC manufacturing method reduces human error, enabling the production of complex components at a speed unattainable with traditional manual machining.

Which materials can be machined with CNC?

CNC machines are capable of cutting, routing, drilling, and milling a variety of materials including metals such as aluminum, steel, plastics, wood, and foam, showcasing the versatility of cnc machining technology.

Is CNC technology used in San Francisco?

Indeed, CNC machining is widely adopted by San Francisco tech companies and local manufacturers for rapid prototyping, electronics, and specialized custom parts due to its precision and efficiency!

What industries rely on CNC machines?

CNC machining is essential for aerospace, automotive, electronics, healthcare, and consumer products, making it indispensable in industries that require the highest quality parts or custom CNC manufacturing.

Are CNC machines expensive to run?

First, CNC machines, despite their larger up-front expenses, offer significant efficiency and speed in the machining process. This often leads to savings over time, especially for complex CNC manufacturing or bulk orders.

Can CNC make custom, one-off parts?

He is very excited about the rapid prototyping capabilities, and we are too. From the prototypes to the custom, one-off designs, it’s perfectly suited for both cnc machining and high precision applications.