Key Takeaways

- Because the type of operating stresses a part will encounter are the primary consideration in CNC machining material selection, defining functionality requirements and matching them to applicable material properties is an important initial step.

- Considering manufacturability and favoring materials that are easy to machine simplifies manufacturing and brings down lead time and costs.

- By comparing the long-term value of materials versus upfront costs and accounting for waste and rework, we are able to deliver economical solutions that manage quality and budget tradeoffs.

- From aluminum alloys and titanium grades to engineering plastics and high-performance polymers, knowing the unique properties and applications of metals and plastics is essential for choosing materials designed for specific industry requirements.

- Evaluating machinability parameters like hardness, thermal conductivity, and chip formation tendencies helps optimize machining efficiency, tool life, and surface finish.

- By integrating advanced finishing techniques, heat treatments, and sustainable material choices, we are able to enhance part performance, extend service life, and support responsible manufacturing practices in line with global industry standards.

CNC machining materials are a category of metals, plastics and composites that suit the requirements of computer numerical control production.

Metals such as aluminum, steel and brass are excellent choices for components that need to be strong or heat resistant.

Plastics like ABS, nylon and PEEK are great choices for tasks requiring a light weight, but high wear strength.

Composites, such as carbon fiber, further provide a blend of light weight and sturdy construction for high-performance applications.

Not all materials are created equal – each option impacts a part’s machinability, cost, and final application.

To choose wisely for a project, it helps to understand the characteristics and compromises of each type.

The following sections disaggregate the choices.

Core Selection Principles

Choosing CNC machinable materials is a complicated process that requires an in-depth analysis of your project specifications and constraints. Each choice determines how the ultimate part performs, costs, and provides value over time. Core Selection Principles for material selection address fundamental criteria that characterize appropriate use worldwide.

Functionality

Performance begins with defining what the role has to accomplish. Identify operational demands by mapping out:

- Load types (tensile, compressive, flexural) the part will face

- Wear and fatigue resistance required for moving or stationary components

- Environmental exposure, such as heat, cold, humidity, or chemicals

- Weight limits and balance between mass and strength

Certain components may demand metals such as stainless steel for tensile strength or corrosion resistance, while others could exploit polymers for lower weight. For instance, nylon’s pliability accommodates moving joints, and aluminum alloys shine in lightweight structural frames.

Never forget to always tailor material characteristics—such as ductility, brittleness, or resistance to weathering—to the job and setting. Outdoor parts might require UV-stable plastics or marine-grade metals whereas indoor components might be fine with cheaper alloys.

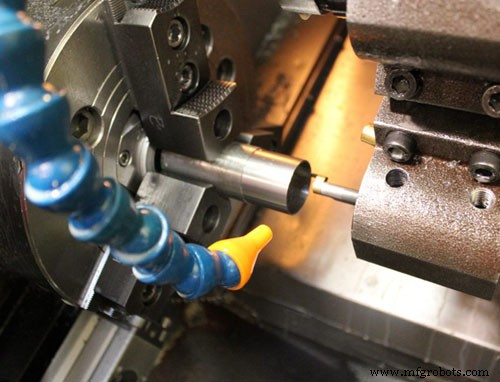

Manufacturability

Good machinability minimizes scrap and maximizes flow. Brass and aluminum, for example, cut cleanly and prolong tool life, while hard alloys or heat-resistant plastics may require reduced feeds or specialized cutters.

Design complexity counts—tight tolerances or complex shapes tend to lean towards the softer, predictable materials. CNC machine restrictions—tool rigidity, spindle speed, coolant application—impact selection as well.

If a job requires custom jigs or diamond-coated tools, costs and time increase. For high-volume production, select materials with the least amount of tool changes and setup times. Sometimes non-metallics such as PTFE or PEEK are selected for ease of shaping and finishing.

Cost-Effectiveness

- Raw material cost per kilogram or cubic centimeter

- Machining time and tool wear rate

- Scrap rate and risk of rework

- Maintenance or lifecycle replacement costs

Upfront savings are nice, but long-term value usually trumps. Titanium is costly yet endures in severe environments. Polycarbonate, while more costly than acrylic, is impact resistant and doesn’t need to be replaced as often.

Waste from machining brittle materials can rack up costs, so consider rework possibilities. Choose the content that hits project goals within budget and without compromising results.

Material Characteristics

Understand the pros and cons of each. Metal might be strong, but plastic frequently triumphs on corrosion resistance and moldability. Certain ceramics offer incomparable hardness for wear parts but can have brittleness.

Always verify that the material’s ductility permits forming to your desired shape. High ductility equals easier to shape, while low ductility poses a risk of cracking. Think about the environment—outdoor parts might require special coatings or alloys, while indoor parts can focus on cost.

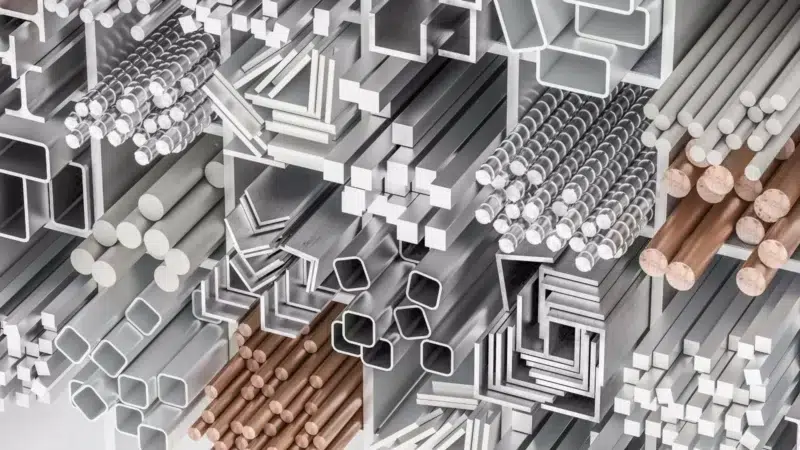

Common CNC Machining Metals

Common CNC Machining Metals CNC machining makes use of an extensive variety of metals, each with unique characteristics and industry standards that act as the benchmark of excellence. Selecting the perfect metal begins with recognizing these fundamental characteristics, weighing mechanical and economic considerations, and knowing where each material excels.

| Metal | Key Properties | Common Applications |

|---|---|---|

| Aluminum | Lightweight, corrosion resistant, easy to machine | Aerospace, automotive, consumer goods |

| Steel | High strength, durable, various grades | Construction, machinery, tools |

| Stainless Steel | Corrosion resistant, hygienic, tough | Medical, food processing, marine |

| Titanium | High strength-to-weight, corrosion resistant | Aerospace, medical implants |

| Brass | Machinable, aesthetic, corrosion resistant | Plumbing, decorative parts, fittings |

| Copper | Highly conductive, corrosion resistant | Electronics, electrical components |

| Superalloys | Extreme strength, heat/corrosion resistant | Aerospace, energy, high-performance |

1. Aluminum Alloys

Aluminum alloys are notable for their light weight and excellent corrosion resistance. Machining shops love aluminum because it clean cuts, extends tooling life and allows for tight tolerances. This results in quicker turn-around times and reduced expenses for tight tolerance components.

Common grades such as 6061 and 7075 provide different strength vs. Weight profiles allowing users to tailor alloy selection to their application. In industries such as automotive and aerospace, aluminum alloys assist in achieving rigorous performance targets without the weight.

2. Steel Varieties

Steel is a CNC machining mainstay because of its combination of tensile strength, hardness and versatility. There are three main groups: carbon steels (like AISI 1045), alloy steels, and stainless steels. Carbon steels do the trick for hard-hitting builds, stainless steel, bolstered with chromium or molybdenum (316 grade) counters rust in demanding environments.

Steel’s toughness makes it indispensable for bolts, shafts, frames and bespoke machinery. It transcends industries, from heavy equipment to tools for the trade. Steel’s versatility extends to specialized varieties as well.

Stainless is the go-to for medical or food, where hygiene and corrosion resistance matter most. Alloy steels, on the other hand, are utilized for extra toughness or heat resistance, such as in the energy or transportation industries.

3. Titanium Grades

Titanium provides a unique combination of lightweight strength, along with excellent corrosion resistance. These properties are why it’s frequently selected for mission-critical aerospace and medical applications, where every gram counts and breakdown is not an option. Various grades, from pure Ti to exotic alloys, perform duties ranging from bone implants to jet engine components.

Machining titanium, however, is challenging—intense tool wear and slow cutting speeds increase expenses and require strategic preparation. Titanium’s application is regulated by rigorous specifications for each grade, making sure finished parts are safe and dependable.

4. Copper and Brass

Copper’s a standout for its conductivity, a must for electronic parts and wiring. Brass, a copper-zinc alloy, is prized for easy machining and a gold-like appearance, so it’s popular in decorative or plumbing components. Both metals are corrosion-resistant, so they’re logical choices for marine equipment.

Brass is a ‘free-machining’ metal, so it’s simple to cut into parts with small or complicated shapes. We turn to copper and brass when conductivity or clean finishes are critical. Brass often finds use in musical instruments too.

5. Specialty Metals

Specialty metals such as nickel-based superalloys fill needs in harsh or high temperature environments. These materials are pricier, but their strength and resistance to heat and corrosion make the price worthwhile in aerospace and energy work.

Exotic alloys, such as newer titanium blends, are now typical for high-stress bearings, turbine blades, and reactors.

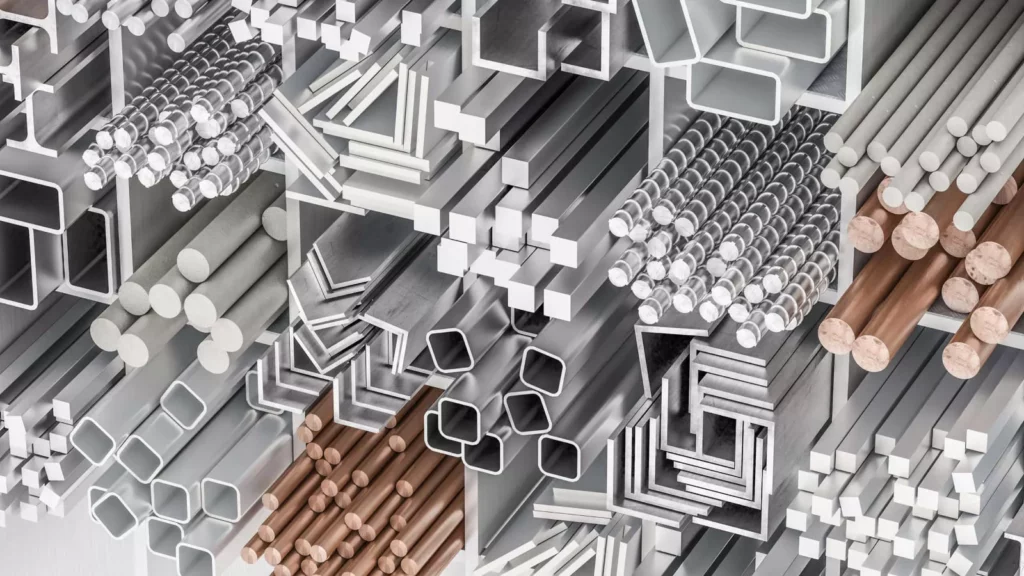

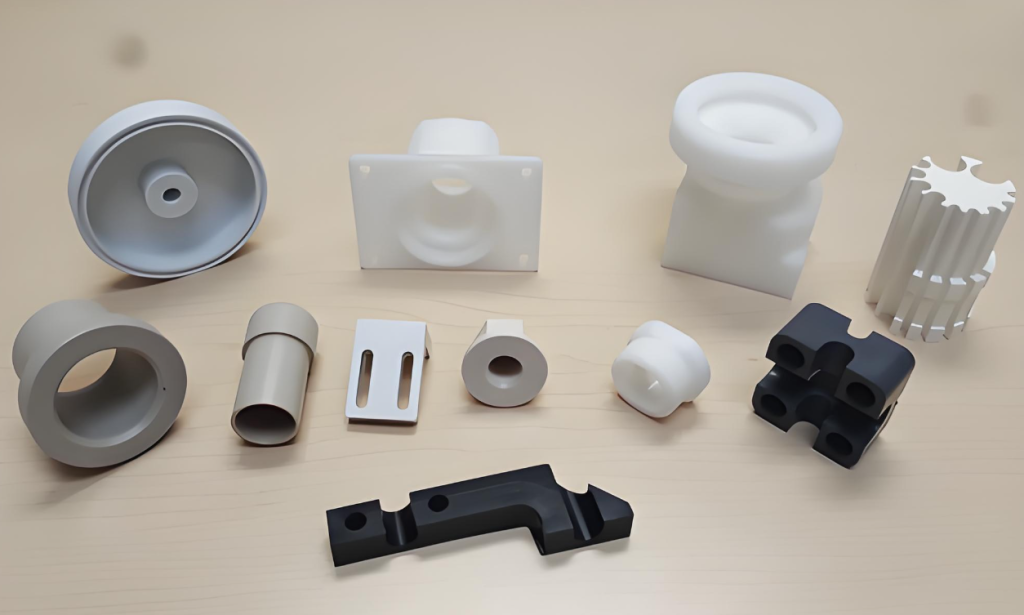

Common CNC Machining Plastics

Among the most common CNC machining materials are plastics, known for their low weight, versatility and chemical resistance. Whether engineering, standard, or high-performance plastics is a decision driven by each project’s needs. We’re now seeing these materials across industries – automotive, such as consumer electronics and health care – as their design and performance benefits come into focus.

Engineering Plastics

Nylon, polycarbonate, and Delrin are the most common engineering plastics because of their toughness, impact resistance, and load bearing shape retention. Nylon 66 in particular is regarded for its strength and wear resistance, suitable for gears, bushings, and structural parts.

Polycarbonate is notable for its impact resistance and stiffness, maintaining performance in both cold and hot environments. Delrin, otherwise known as acetal, is a favorite when close tolerances are needed due to its high stiffness and low friction.

Engineering plastics are prized for their resistance to high temperatures and harsh chemicals, making them suitable for environments where metal would corrode or break. Their machinability lends itself to fine detail and tight fit, so they’re often employed where precision is paramount.

Standard Plastics

They offer common plastics, like ABS and acrylic (PMMA), when cost and convenience trump mechanical properties. ABS is one of the easiest and cheapest plastics to machine, so it’s a go-to for prototypes, cases or enclosures that aren’t subject to heavy loads.

Acrylic is prized for its clarity, light weight, and toughness—commonly selected for displays, covers, or panels. These plastics are simple to mill and shape, leaving them suitable for parts requiring quick modifications or high volume manufacturing.

Although not as strong as engineering plastics, standard plastics’ looks, colors and finishes are often better for exposed components. They’re best utilized in low-stress environments where price is paramount.

High-Performance Polymers

High-performance polymers, like PEEK and PTFE, bridge the gap for extreme use cases. PEEK is valued for its combination of strength, thermal resistance and chemical stability. It stands up in environments where most plastics can’t, including aerospace, medical, and oil and gas.

PTFE, low friction and chemically inert, is used in harsh chemical plants or high temperature seals. They can be hard to machine due to their special composition and may require slow feeds or specialized tooling.

Still, their advantages are obvious for components that have to function in the toughest environments.

The Machinability Matrix

The machinability matrix is a handy chart that rates materials based on how easy they are to be machined. It helps engineers and machinists select the appropriate material for a project, identify the optimum machining parameters, and strike the right balance between cost and performance.

The matrix compares materials to a benchmark, typically C36000 Brass or AISI B1112 steel, both 100%. Anything rated over 100% machines more easily. Materials such as aluminum (6061-T6) fall close to 90-95%, whereas titanium (Grade 5) can descend to 20-25%.

It includes hardness, thermal conductivity, and chip formation because they all directly influence machinability.

| Factor | Description | Example (Machinability %) |

|---|---|---|

| Hardness | Resistance to deformation and wear | C36000 Brass (100%), Ti G5 (20-25%) |

| Thermal Conductivity | Ability to transfer heat away from cut zone | Al 6061-T6 (high, 90-95%), SS 304 (low, 45%) |

| Chip Formation | How material breaks and forms chips | Free-machining steel (100%), Tool steel (low, 35-40%) |

Material Hardness

Hardness, measured by Rockwell, Brinell, or Vickers scales, indicates how resistant a material is to being deformed by an applied force. Harder materials, such as tool steels, are more long-lasting at difficult tasks but result in higher cutter wear and require slower cutting speeds.

Softer metals such as brass or free-machining steels cut quicker and with less tool wear, but may not have the strength required for high stress parts. Machinists often have to balance the benefit of a hard, tough part versus the increase in machining time and cost.

Hardness testing insures that each batch conforms to established specifications. For high-wear jobs, like gears or bushings, hard materials are a savvy choice, but they reduce throughput and increase tool costs.

Thermal Conductivity

Thermal conductivity indicates a material’s ability to distribute heat away from the cutting zone. Metals such as aluminum are excellent conductors of heat, allowing heat to be transported away quickly. This characteristic not only helps keep parts cool but tools sharp.

Unlike aluminum, stainless steel and titanium, with lower thermal conductivity, trap more heat at the cut, risking tool damage and surface flaws. A nice thermal conductivity, in other words — which translates, of course, into faster machining speeds and smoother surface finish.

When selecting a material, take into account whether heat buildup might lead to parts warping or tools wearing quickly. It can be key in high-speed or high-volume runs.

Chip Formation

Chip formation is the key to both efficiency and tool life. Others, such as free-machining steels with sulfur or lead additions, chip into little, easy-to-clear bits. This results in machining slicker and maintains the cut cleaner.

Others, such as titanium or certain stainless steels, produce long, stringy chips that tangle and jam the operation. Cutting speed and feed change the kind of chip. High speed in soft metals tends to produce short, curled chips.

Low speeds or hard materials might require specialty tooling or coatings. Good chip removal keeps the part surface smooth, holds tight tolerances and prevents heat build-up.

Enhancing Part Performance

Optimizing part performance begins with making the right material and tooling and process decisions. CNC machining provides unsurpassed control over these variables, enabling engineers to craft precision, robust parts for demanding applications. The right combination of design, heat and surface treatment can extend the life of every piece, improve performance and keep it looking sharp.

- Select optimal materials for specific applications

- Use heat treatment to strengthen and harden metals

- Finish surfaces to improve both looks and function

- Anodize and plate to protect from wear and corrosion

- Use FEA and simulations to predict performance

- Match machining strategies to material properties

- Monitor production with smart systems for best results

Heat Treatment

Heat treat alters the behavior of metal by heating and cooling it in controlled phases. This can make steel harder or more flexible, so the part is just right for its job. Engineers select treatments such as annealing, quenching, or tempering based on the eventual application of the part.

For instance, quenching and tempering adds toughness to steel gears for heavy machines, and annealing makes aluminum housings less brittle. Heat treatment influences the machinability of the part, its strength, and its ability to resist cracking under stress.

When done right, heat treatment meets close performance requirements, such as rendering surgical instruments hard enough to slice through but not so hard that they break.

Surface Finishing

Surface finish counts for more than appearance. A polished CNC machined finish reduces potential stress risers, assisting parts to resist strain. Polishing, bead blasting, and vapor polishing all leave a distinct fingerprint.

Polishing can make a lens crystal clear for medical devices, while bead blasting leaves a matte finish on industrial housings for grip and durability. Coatings or surface treatments can keep rust and wear at bay, or reduce friction where parts come together.

Every finish is selected to endure as long as necessary and suit the task. Good surface finishing is not an afterthought. It’s engineered into the design process to meet precise specifications, be it for aerospace, electronics or implements.

Anodizing and Plating

Anodizing enhances aluminum’s surface, rendering it stronger and more corrosion resistant. This is critical for plane fuselages or external hardware. Bright colors or matte looks can be produced, as well.

Plating–nickel or chrome for example–can provide additional protection, prevent corrosion, and even make a part ‘pop’ for consumer products. Both make parts stand up and work in hard places.

The benefits go beyond function: anodized parts stay light, plated ones reflect less wear. Yet, every process has its own guidelines to maintain waste and pollution levels low, which are relevant for worldwide regulations and eco-friendly objectives.

The Sustainability Factor

Sustainability in CNC machining influences the way businesses consume resources and dispose of waste. Because CNC cuts with precision, less material becomes scrap. It’s cost-saving and less burdensome to the environment.

Evaluating the sustainability of CNC materials is about examining the lifecycle of each one. Metals such as aluminum and steel are commonly selected because of their durability, however mining and refining them can be detrimental to the environment. Recycled aluminum or steel reduces that impact. Composites and plastics should be from recycled sources, or have recycling plans for their end use, if selected. Material lifecycle checks—sourcing, machining, and disposal—provide a comprehensive perspective on the green score of each choice.

Second, recycled materials are essential for transitioning to sustainable manufacturing. Using recycled metals or plastics reduces the demand of companies for virgin materials. For instance, recycled aluminum preserves as much as 95% of the energy required to produce virgin aluminum. They can reserve metal shavings and trimmings for recycling, breathing new life into old waste. Certain companies even require their suppliers to demonstrate recycled content in their raw stock to satisfy internal objectives and external regulations.

Going sustainable is more than just selecting the right content. CNC shops are using less energy by switching to LED lights and running machines with high energy ratings. IoT-connected CNC systems monitor energy consumption and identify areas where waste occurs, allowing operators to adjust processes in real time. New CAD/CAM software can plan the most efficient tool paths, so fewer passes and up to 20% less energy used per job. These changes all contribute to a reduced carbon footprint.

The industry now demands greener options from vendors. A lot of buyers want evidence that a company utilizes energy-efficient machines and recycles its waste. By taking these steps, CNC shops demonstrate that they stay current with industry standards and are invested in the entire lifecycle of their products.

Conclusion

Well, good CNC parts require the right material. Metals such as steel and aluminum provide robust, durable components. Plastics such as ABS or nylon are ideal for lightweight, supple configurations. Every job demands a clean matching of needs and properties. The machinability matrix cuts waste and saves time. Selecting the appropriate materials can reduce expenses and increase your green footprint. Shops everywhere seek this trifecta of speed, low scrap, and resourceful intelligence. The right steps yield parts that endure and suit their task. Interested in diving deeper into selecting the ideal CNC material for your upcoming work? Leave your comments or questions below and let’s continue this conversation.

Frequently Asked Questions

What are the main factors to consider when choosing CNC machining materials?

Choose materials flexibly according to strength, machinability, price and end-use criteria. Think about environmental impact and part performance for optimal results.

Which metals are most commonly used in CNC machining?

Aluminum, steel, stainless steel as well as brass are popular. These metals provide good machinability, durability and price for many applications.

What plastics are suitable for CNC machining?

Common plastics are ABS, nylon, polycarbonate, POM (acetal). These provide good machinability, strength and chemical resistance for many parts.

How does machinability affect material choice?

Good machinability translates into quicker production, less tool wear, lower cost. Materials such as aluminum and certain plastics are generally simpler to machine compared to more resilient metals.

How can material choice enhance part performance?

Picking the ideal material enhances longevity, accuracy and performance. It helps parts endure mechanical, thermal or chemical stresses in their working environment.

Are sustainable materials available for CNC machining?

Indeed, recycled metals and bioplastics are increasingly accessible. By using these materials, you reduce environmental impact and preserve part quality.

Is there a standard method to compare machinability of materials?

Yes, machinability matrices and rating charts assist contrast how easily varied materials may be machined. These tools facilitate economical material selection.