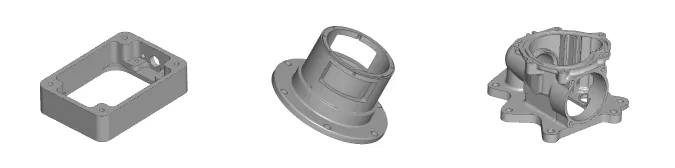

One-Stop OEM/ODM Carbon Steel Casting Parts manufacturers

High-Quality Carbon Steel Casting Parts

Start A New Quote

Start to Upload Your Files

Start to Upload Your FilesSTEP STP SLDPRT IPT PRT SAT IGES IGS CATPART X_T OBJ STL files

Focus on Carbon Steel Casting Parts

Our Carbon Steel Casting Parts Are Engineered to Meet the Demanding Requirements of Applications Worldwide. to discuss your project requirements. Get in touch to discuss your project

I don't have complete drawings, can I send inquiry?

Yes, we can help you analyze based on your description, samples and photos.

I am not sure if you can do my parts?

Most of our customers come to us because “others say they can’t do it”.

Are you a factory or a trader?

We are a factory and have a project management team that can handle the technology, cost and delivery at the same time.

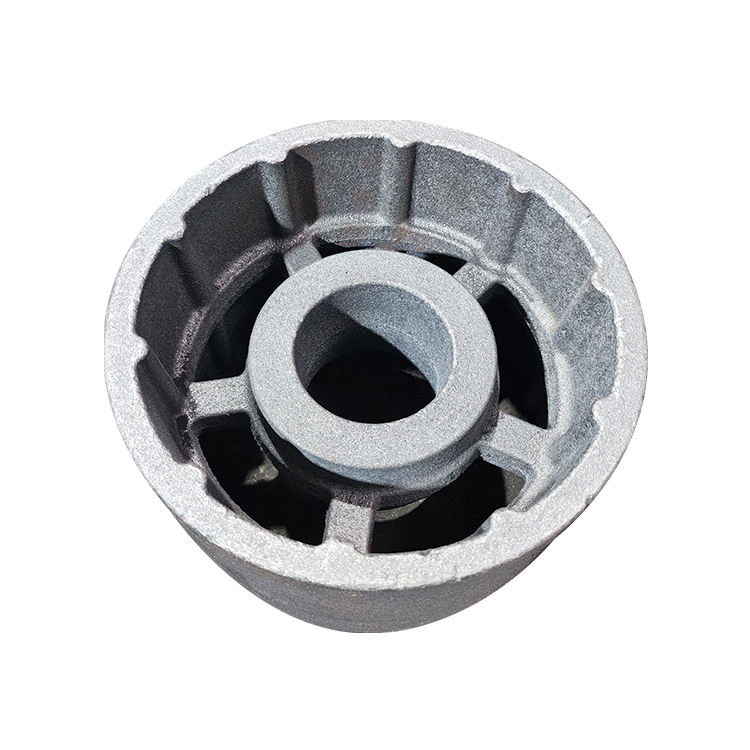

Our Expertise in Carbon Steel Casting Parts

We specialize in engineering-grade carbon steel casting components designed for load-bearing, impact-resistant, and cost-efficient industrial applications. Our manufacturing capability covers thin-wall sections, complex internal runners, and heavy-duty geometries required for harsh mechanical environments.

Using precision investment casting, sand casting, and controlled pouring & solidification simulation, we produce custom carbon steel assemblies for automotive, construction hardware, mining equipment, lifting devices, agricultural machinery, and energy-sector components.

Our size capability ranges from 0.1 to 24 inches, with part weights from 1 ounce to 50 pounds, supporting both prototype and stable mass-production batches. Every casting undergoes mechanical-property verification to ensure required strength, toughness, fatigue resistance, and dimensional consistency based on final operating conditions.

Our Manufacturing Approach

To ensure consistent casting quality, we've broken down “control” into tangible data and processes: material batch traceability, comprehensive casting parameter logging, pre-production simulation validation, and digital verification for every batch inspection—replacing reliance on master craftsmen's intuition.

Alloy Composition and Melting Control

We apply spectral analysis and in-furnace composition adjustments for carbon and alloy steels, such as AISI 1020, 1045, 4130, 4140, and 8620, as well as ASTM A216 WCB. Focus points include C, Mn, Si, S, P, Cr, Mo, Ni precision control to achieve target strength, hardenability, and weldability, while preventing porosity, segregation, and grain coarsening.

Engineering Design of Mold & Feeding Systems

Mold engineering is optimized using flow and solidification simulation to control shrinkage, hot spots, crack-risk zones, and inclusion trapping.

Heat Treatment for Mechanical Performance

Heat-treatment processes vary based on grade and performance requirements, including:

Precision Machining & Quality Inspection

CNC finishing achieves dimensional accuracy of ±0.05–0.1 mm with CMM verification for complex tolerances. The surface finish typically reaches a Ra of 3.2–6.3 μm, depending on the casting and machining stages. Complete inspection options are available, including UT, MT, tensile, hardness, metallography, run-out, thread gauge validation, and alignment with engineering drawings and acceptance standards.

What are the Advantages of Carbon Steel Casting Parts ?

Suppose you're unsure whether carbon steel is the right material. In that case, we help evaluate stress-load conditions, cost trade-offs, heat-treatment feasibility, and fatigue life through early-stage manufacturability assessments and process simulations.

Secondary Operations and Treatment of Carbon Steel Casting Parts We Offer

How to Work With us

Provide 3d drawings

Evaluate the quotation

Manufacturing

Order delivery

Get 3-day standard lead times on simple parts between 10 mm x 10 mm and 200 mm x 200 mm. Upload your part to see if it’s eligible.

Frequently asked questions

Drawing evaluation: 1-2 business days

Prototype production: 5-10 business days

Small-batch production: 10-15 business days

Large-scale production: 15-30 business days

Rush service: 72-hour rush service available (additional fees apply)

We have established a comprehensive quality management system:

ISO 9001:2015 Certification: International quality management standard

First Article Inspection: 100% confirmation of the first piece before mass production

Process Control: 100% inspection of critical processes

Finished Product Inspection: Full dimensional inspection using CMM coordinate measuring

Quality Traceability: Complete production and inspection records

We support both small-batch prototyping and large-scale production. MOQ starts from as low as a few dozen pieces, and high-volume orders up to hundreds of thousands are welcome.

Yes. Besides producing according to drawings, we provide DFM (Design for Manufacturability) support to reduce costs and improve efficiency.

Pricing is based on material, process complexity, order volume, and delivery requirements. We aim to offer the most cost-effective solution for every project.

We serve automotive, machinery, electronics, medical devices, and energy sectors. From precision parts to structural components, we have extensive expertise.