Key Takeaways

- Rapid tooling provides manufacturers with leading edge techniques that allow them to generate tools and parts more quickly and less expensively, leading to significantly reduced design cycles and increased flexibility for small or medium scale production.

- Combining state-of-the art digital design and simulation technologies for accurate, error-minimized tool creation with clear cross-team communication to streamline every step of the process.

- Direct methods, like 3D printing, and indirect methods, such as casting and molding, each offer distinct advantages and disadvantages, so the choice of technique is largely driven by factors including production volume, material specifications, and design intricacy.

- Used strategically, rapid tooling can give your business that competitive edge by speeding your time-to-market, increasing design freedom and lowering manufacturing costs to boot.

- Speed, cost and quality must be carefully balanced in rapid tooling projects. Companies need to decide intelligently about trade-offs in order to obtain the best results for particular projects.

- Ongoing knowledge capture, agile integration, and strategies that mitigate risk are key to pushing past the constraints in rapid tooling, delivering more successful product launches and operational efficiency for the long haul.

The term rapid tooling refers to manufacturing molds or parts quickly for product fabrication, often using technologies such as 3D printing or CNC machining. A lot of product teams choose rapid tooling to reduce lead times and cost, because it functions for both prototype and short runs of production.

Whether it’s car making, medical devices or consumer electronics, these teams leverage rapid tooling to validate fit, feel and function prior to scaling up to large runs. With rapid tooling, teams identify errors or design issues in their infancy, which keeps costs under control and makes modification simple.

The following sections explain rapid tooling — how it works, what technology is used, and why it’s important for those seeking speed and low-cost manufacturing.

What is Rapid Tooling?

Rapid Tooling (RT) is the group of techniques and technologies to produce molds, dies or other tooling, quickly and cheaper than conventional methods. It became significant in the late 20th century with emerging technologies such as additive manufacturing and more precise CNC machines.

These techniques assist get actual parts to you fast, whether for validation or to jump-start manufacturing. Rapid tooling is most effective at lower quantities, typically 1 to 10,000 parts, and significantly reduces time to market. Industries ranging from automotive to health care utilize these tools to accelerate their product development lifecycles.

It can be either direct or indirect and frequently utilizes soft metals or polymers for tooling, resulting in a quicker and less expensive process with molds having a shorter lifespan.

1. The Core Concept

Rapid tooling utilizes both direct and indirect approaches. Direct tooling refers to fabricating the mold or insert directly from the CAD file, typically via 3D printing. Indirect tooling is when you make a master model first that then helps form the actual mold.

It’s not the slow, multi-step process of traditional tooling that takes months and requires lots of manual incrementing. The primary benefit of rapid tooling is its speed. It can slash lead times to just 24 hours, versus four to eight weeks for old-school tooling.

This allows teams to test, debug, and refine designs with far less risk and expense. The trick is using softer metals like aluminum, or even silicon or polymer based molds. These materials keep it cheap and rapid but restrict the mold’s lifespan to a few thousand cycles or fewer.

That’s why rapid tooling is chosen for low to medium runs or when test parts are required immediately. Major sectors such as automotive, aerospace and consumer products turn to it to stay ahead of rapid markets.

2. The Bridge Tooling Role

Bridge tooling provides the bridge between prototype and production. It allows teams to produce actual, functional parts in small quantities—just enough to test the market, perform safety verifications, or obtain early customer feedback.

Utilizing less expensive materials and faster techniques, bridge tooling provides an economical means of validating a design’s functionality prior to committing to hard, high expense production molds. The big victory is time and money saved for companies.

Rather than placing big bets on a final tool, they can iterate and don’t go to mass production until they’re certain the design is right. This keeps waste down and allows teams to respond to new demands or issues rapidly.

3. The Prototyping Distinction

No, rapid tooling is not just rapid prototyping. While both utilize speedy, digital processes, rapid prototyping is concerned with creating model parts—typically for appearance or fit testing. Rapid tooling, by contrast, makes actual molds or dies, so teams can produce parts from the correct material and to the precise specifications.

This is to say, they can test part function and not only aesthetic. With rapid tooling, these early design verifications occur in tangible materials, which results in more effective testing and less vulnerability prior to a full launch.

Teams can utilize high-tech features like conformal cooling, which can reduce cooling times by as much as 66% and accelerate the entire process. That’s how you get products to market a lot faster and with a lot less surprises.

4. The Production Impact

Rapid tooling services accelerate the entire production process, allowing teams to use less while saving more. With rapid tooling parameters, production runs can begin earlier, and modifications become more achievable.

The Rapid Tooling Process

Rapid tooling disrupted more traditional manufacturing techniques when it initially emerged in the late 20th century. This transition brought on fresh rapid prototyping techniques such as additive manufacturing and precision CNC machining. Now, hundreds of companies can get from pixel to working mold in a matter of days or weeks, leveraging rapid production tooling to enhance efficiency.

Rapid tooling is typically for shorter production runs—as many as 10,000 parts—or prototypes when the design is close to completion. The process depends on collaboration and innovation to maintain speed and reduce waste and expense. Digital tools are key at every stage, from design through to fabrication and testing of each rapid tool.

The main stages of rapid tooling are crucial for ensuring that the manufacturing process meets the prototyping needs and quality standards required for production parts.

-

Digital Design – create a precise drawing or model using digital design tools

-

Tool Making – make the tool or mold with rapid techniques such as 3D printing or quick machining

-

Part Manufacturing – utilize the tool to produce final parts

-

Quality validation – inspect and validate to ensure the tooling and end parts satisfy required specifications

Digital Design

Digital design is what allows rapid tooling to be so fast and adaptable. Computer-aided design (CAD) software allows teams to create detailed 3D models of tools or molds, which can be used for simulations and rapid prototyping. With CAD, engineers identify issues and resolve them before any actual materials are employed.

More importantly, it saves time and money. Simulations are critical to this step. They assist in anticipating how the tool will perform in actual application—such as how heat will transfer through the mold or where stress will accumulate. Virtual testing reduces errors and mitigates risk.

For instance, validating cooling channels in a digital twin allows for conformal cooling, which reduces cool-down times by as much as 66%. That translates into quicker iterations and reduced unavailability. By eliminating manual steps and accelerating feedback, digital design helps prevent typical mistakes and keeps projects on track.

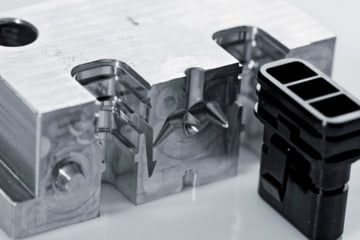

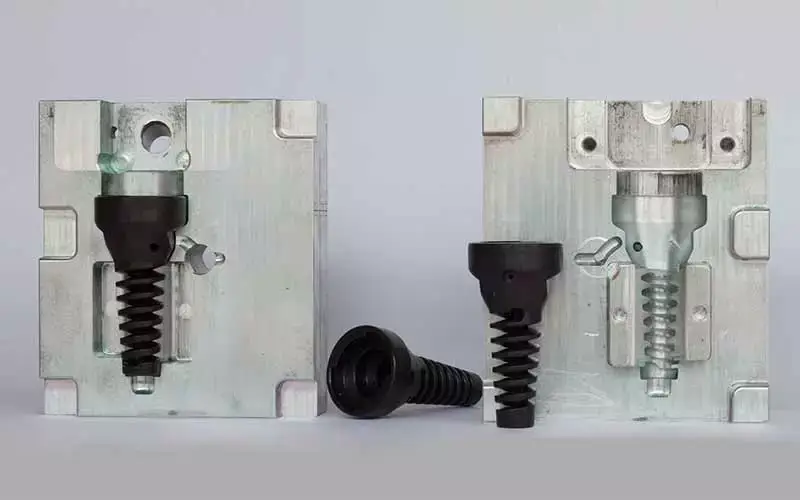

Tool Creation

There are two main ways to make tools: direct and indirect tooling. In direct tooling, the tool or insert is created straight from the digital model, typically through 3D printing or CNC machining. Indirect tooling requires that a master pattern be created first, which is then used to form the final tool.

The alternative is to choose the right path for the particular work and pace. Materials matter a lot! Softer metals like aluminum or steels are common for quick-turn molds, but they don’t last as long as hardened steel. For instance, aluminum molds can last a couple thousand cycles, silicone or polymer molds only a few hundred shots.

Metal binder jetting is a newer technique that turns hard tooling into days faster. 3D printing is typically reserved for intricate geometries or when rapid modifications are necessary. It’s the quickness of tool generation that makes rapid tooling stand out — slashing lead times and facilitating design iterations.

Part Manufacturing

With your tooling, rapid tooling makes it much faster to go from design to real parts. Once a mold is prepared, it can be utilized for injection molding, die casting, or other processes. This is useful for prototypes and small to medium runs.

The big advantage is that by being able to test functional parts early you’re catching design issues well before the eventual full launch. For instance, a squadron might utilize rapid-tooled aluminum mold for manufacturing a run of plastic parts for combat zones.

If changes are necessary, the digital design can be modified and a new tool manufactured rapidly, circumventing the months-long delays. It’s this flexibility that’s a big reason rapid tooling is so prevalent in speed-sensitive markets such as consumer electronics or medical devices.

Quality Validation

Quality checks are paramount in this stage. Every tool has to be tried out prior to producing parts. This usually implies producing a prototype run and verifying measurements, compatibility, and usage. Issues are detected early, resulting in time savings down the line.

The results of these tests are fed back to the design team. They can then adjust the tool or the process prior to the beginning of the mass production. This loop controls errors and maintains quality.

It’s a glorious cycle: good validation = less waste, less cost, happier clients.

Rapid Tooling Methods

Rapid tooling strategies assist in fabricating tools and molds at a significantly faster rate than traditional techniques, employing digital design and sophisticated equipment. These approaches allow teams to experiment with new concepts, experiment with modifications and receive input rapidly. The right method can save tons of time and money.

Which to choose, direct or indirect, is determined by the project requirements—dimensions, shapes, quantity of components, hardness of molds. As the machines and the software improve, rapid tooling continues to become quicker and more flexible, something that teams everywhere should value.

Direct Methods

Direct methods in rapid tooling refer to producing the tool or mold directly from a CAD file, eliminating the need for a master pattern or intermediate steps. Among these rapid prototyping techniques, 3D printing stands out, including varieties like fused deposition modeling (FDM), SLA, and metal binder jetting. These rapid tooling services can manufacture metal or plastic tooling in just days, making them ideal for quick production needs.

These direct methods are particularly beneficial for early prototypes or when you require a few parts urgently. For instance, metal binder jetting can create hard tooling materials from stainless or tool steel, ready for testing or low-volume production. This expedites design verification and enables teams to prototype actual components under real operating conditions, ensuring efficiency in the manufacturing process.

By bypassing much of the manual work involved in traditional tooling methods, these rapid tooling techniques minimize mistakes and reduce the chances of delays, significantly enhancing production speed and efficiency.

- Advantages:

- Fast turnaround and reduced manual work.

- Great for short runs and design modifications.

- Reduces initial prototype expense.

- Can utilize advanced features such as conformal cooling channels that reduce cooling times by up to 66%.

- Limitations:

- A few printed molds are used up quick, just a few hundred to a few thousand cycles.

- Not perfect for very high-volume production.

- Surface finish and accuracy might require post-processing.

Indirect Methods

Indirect techniques utilize a pattern or master model to fabricate the final tooling, usually by casting or molding. Silicone rubber molds, soft tooling, investment casting all fall here. These come in handy when the design is complicated or the tool has to be produced in non-printable materials.

The indirect methods take complex shapes in stride. For instance, a master pattern may be 3D printed, then used to cast a mold in aluminum or a high-heat polymer. This allows teams to work with materials that withstand relatively high injection temperatures (up to roughly 238 °C @ 0.45 MPa).

Soft tooling with silicone or polymer can crank out hundreds, and hard tooling in aluminum or steel is good for thousands.

Indirect and direct approaches frequently collaborate. A group could print out a design, then cast it into a longer lived mold. Or they may use indirect methods for the final tooling after a number of quick direct-method prototypes.

- Advantages:

- Handles complex or detailed designs.

- Ideal for larger molds and more demanding materials.

- Provides a soft or hard tooling option to meet your production requirements.

- Limitations:

- More steps, so occasionally slower than direct processes.

- More practical work required.

- Costs go up for small quantities of parts.

Choosing the Best Method

Ultimately, what determines the best rapid tooling method to use is examining the project’s size, shape, part quantity, and tool hardness. For runs under 1,000 parts or with lots of changes, soft polymer molds or direct printing cut costs and time.

For larger scale projects hard tooling from aluminum or steel is superior, even if it’s a little slower to start. Technology continues to advance. Metal binder jetting and conformal cooling, for instance, render molds more speedy and durable, bridging the divide between quick and conventional tooling.

Key Selection Criteria

Rapid tooling is unique among the advanced manufacturing techniques for its speed, flexibility, and capacity to manage complex part designs. The type of rapid tooling you select depends on a variety of factors, ranging from production objectives to design requirements. Some of the key selection criteria are production volume, material selection, part complexity and speed-versus-durability. All of these influence the end result, price and turnaround of the project.

The material selection impacts the tool’s wear resistance and cycle time, as well as the quality of parts produced. Material decisions affect not only the up-front cost but the long-term cost by defining the mold’s longevity. The mechanical and thermal properties of your material selection affect part performance, particularly for highly demanding applications. Integrating with the right material can solve project-specific targets, like minimizing cooling time or facilitating more complex geometries.

Production Volume

Production volume is key when selecting the appropriate tooling route. Rapid tooling is ideal for low to medium production runs, where costs and lead times need to be managed. Under 10k parts or so, it generally makes more sense to rapid tool because of the smaller investment and quicker turnaround. Instead, conventional tooling is perfect for jobs greater than 5,000 or even 10,000, as the higher upfront expense becomes amortized across a larger number of pieces.

For a minimum volume project (less than 1,000) – polymer inserts and silicone molds are often your friend. These allow them to hold expenses low and enable teams to go from design to finished part in days or weeks, not months. High-volume production, on the other hand, warrants the expense of steel molds, which have a longer life and more cycles. Rapid tooling is extremely flexible to changes in production size, making it great for pilot runs or testing the market before scaling up to full production.

Material Choice

Material choice is always a key step in rapid tooling services. Rapid tooling processes utilize softer metals such as aluminum or soft steels, which reduce lead time and cost. For example, aluminum molds cool quickly and enable rapid cycles, although they wear out faster than hardened steel, making them suitable for only a couple thousand parts. Silicone and polymer inserts are typical for very short runs or prototyping, particularly in rapid prototyping techniques. In contrast, traditional tooling employs hardened steel that can withstand hundreds of thousands of cycles, but it is slower and significantly more expensive to produce.

The right material is project dependent. For functional testing or end-use parts, the tooling material must align with your production resin or metal. Some projects, such as those in the medical or electronics fields, require materials that can maintain tight tolerances or resist certain chemicals, making the selection of tool material crucial for quality and cost-effectiveness.

Part Complexity

Complex parts test rapid tooling to the edge. When shapes get tricky with deep undercuts or fine features, conventional tooling begins to sweat in terms of time and expense. Rapid tooling, particularly with 3D printed inserts or conformal cooling, can reduce the lead time to a week or two. That’s a huge change from the up-to-8-weeks required for conventional steel tooling. More crazy parts also translate to more need for attention to detail during the design since bad planning will be expensive to fix in rework.

High-level quick tooling allows teams to experiment with audacious concepts—such as lattice or intricate surface textures—that would be impossible with traditional machining. This paves new avenues for product innovation, but requires engineers to collaborate with toolmakers early to prevent expensive blunders down the line.

Speed vs. Durability

While rapid tooling delivers fast mold turnaround, you sacrifice tool life. Softer they are the faster you can make them but less parts per tool. For short run projects, this exchange is reasonable, particularly when time-to-market is important. If the work demands hundreds of thousands of parts, however, durability leads the way, and timeless steel-tool favorites prevail.

Finding that balance comes down to project scope and budget. Teams should balance how many units they need, their timeline, and the frequency that the tool will require replacement. For most, a blend of rapid and traditional tooling is the optimal way forward.

Strategic Business Advantages

Rapid tooling is one of the best ways for businesses to stay on pace with quick markets and lean operations. By utilizing rapid prototyping techniques, it targets the rapid tooling of molds, dies, and prototypes, assisting in cost and cycle time reduction. Businesses leveraging rapid tooling services can respond to demand shifts while remaining competitive and cutting edge.

Market Acceleration

Rapid tooling allows companies to bring new products to market much more quickly. With the capability to manufacture tooling and components in weeks, not months, companies can accelerate new launches and capitalize on trends. This is particularly important in sectors such as electronics and health care, where product life cycles are brief and customer requirements evolve rapidly.

The strategic edge is quick iterations. If a proto needs tweaks, rapid tooling enables you to implement those changes and re-test with minimal delay. This flexibility enables agile manufacturing, where teams can shift direction based on input.

As an example, a tech startup can iterate from idea to pilot production in days, responding to input from nascent users. They get a genuine edge over lethargic competitors by being the first with new functionality or gap filling.

Cost Optimization

Rapid tooling reduces the cost of producing new products. Conventional tooling can mean a heavy upfront commitment to equipment and labor. With rapid tooling, the easier process and reduced number of steps reduce those costs, critical for companies operating on a small budget.

The techniques minimize costly manufacturing tooling, enabling businesses to produce small or medium runs effectively. This comes in handy for companies experimenting with new markets or catering to niche needs.

Through using less material and generating less waste, rapid tooling also contributes to resource management. When companies save on manufacturing and material costs, they can be more profitable.

Design Freedom

With rapid tooling, design constraints are much less than with traditional tooling. Enterprises could produce components that have complex form, internal voids or elaborate details, without any specialized tooling. This design freedom is huge for teams looking to experiment with new ideas or differentiate their offerings.

If design changes are necessary, you can make them within days. This allows concepts to be experimented on, evaluated, and improved rapidly. Adaptability in design creates more innovative solutions and allows companies to address individual demand.

For instance, a medical device manufacturer can customize offerings to expand across various patient segments, increasing its appeal and fit in the market.

Risk Mitigation

- Use early prototypes to spot flaws before full production.

- Make fast changes based on real-world testing.

- Keep the tooling process short to avoid costly mistakes.

- Scale from small batches to larger runs as confidence increases.

Early prototyping allows teams to identify and address design problems. Swift modifications in response to test results reduce rework and scrap.

It helps facilitate safer product launches. With less danger, companies are able to introduce new offerings more frequently.

Balancing Speed, Cost, and Quality

At the center of rapid tooling services is balancing speed, cost, and quality. These rapid tooling parameters all influence a project’s ability to hit its objectives and how companies react to tight timelines and changing market needs. To optimize this balance, it’s essential to make smart, strategic choices about your tooling materials, design complexity, and production requirements.

The Trade-Off Triangle

Speed, cost, and quality are the vertices of a triangle in which moving one frequently impacts the others. In rapid tooling, slashing lead times to as little as 24 hours can allow companies to get products to market quickly, but potentially at the expense of durability or sophistication.

For instance, aluminum molds are faster to make and less expensive than steel, but wear out in far fewer cycles — making them ideal for short runs or prototypes. Navigating these trade-offs begins with understanding your project’s ultimate objectives.

For example, if your target is under 1,000 parts, you can use polymer inserts or silicone molds made from 3D printed patterns to keep cost low without a big dip in quality. If longer tool life is required, a company might opt for steel, despite its requiring more time and money initially.

Hybrid approaches—mixing tooling methods—allow companies to dial in the balance. There’s no one-size-fits-all; the right blend is a function of balancing speed, cost and quality against what your business values most.

Agile Integration

Agile makes rapid tooling flexible. By chunking projects into manageable steps and promoting regular feedback, teams can identify issues early and adjust before they become expensive. This keeps production agile, particularly when you’re working to a hard deadline or need to redesign on the fly.

With agile, companies can try out different materials, such as moving from aluminum to softer steel in the middle of the project if the part count expands. This flexibility facilitates continuous optimization, since each iteration is a learning opportunity.

It helps to keep workflows fluid, even with complicated or fluid design requirements. The effects are shorter project timelines and tighter alignment with business objectives. Agile integration reduces waste.

Teams invest only where it counts, saving cost and time, all the while maintaining a tight control on part quality.

Overcoming Limitations

Rapid tooling has its constraints, particularly with tool life and design complexity. Softer materials might survive a few thousand cycles, and complex geometries will decelerate production or increase expenses. Overcoming these obstacles frequently involves experimenting with innovative cooling techniques, such as conformal cooling, which can reduce cooling times by around 66%.

Creativity—like integrating 3D printed components with conventional tooling—allows the possibility for excellence. Keeping up with innovations enables teams to evolve with requirements and maintain excellence, even when stretched thin.

A discipline of learning—going back over each project and applying the lessons—allows teams to identify their vulnerability and get better quickly. It’s about staying process-sharp, so every new project goes a little smoother than the last.

Conclusion

Rapid tooling slashes time and expense for parts. Shops can try out new concepts quickly. They team utilize tool such as 3D print, soft molds and simple cast. There are benefits and drawbacks to both approaches. Makers choose what suits the task best. Companies experience tangible benefits, such as faster time to market and reduced material waste. Others use rapid tooling to risk audacious shapes or repair hiccups on the fly. The combination of velocity, cost and part robustness demands crisp decisions. A lot of the fast movers in this space define the speed for everyone else. Want to ride the shift? Stay on top of new equipment, learn through hands-on experience, and exchange advice with your peers. Drop your wins or stumbles down below—let’s innovate better together.

Frequently Asked Questions

What is rapid tooling?

Rapid tooling is a process that leverages advanced technology to create rapid molds or tools quickly, significantly accelerating product development and shortening time to market in the manufacturing industry.

How does rapid tooling benefit businesses?

Rapid tooling services significantly reduce manufacturing costs, compress lead times, and leverage rapid prototyping techniques, allowing companies to be fast and nimble in response to market changes and customer demand.

What are the main methods of rapid tooling?

The primary processes of direct and indirect rapid tooling techniques, including 3D printing and CNC machining, leverage soft tooling materials, each offering varying advantages in speed and cost.

What factors should be considered when choosing a rapid tooling method?

Important considerations in rapid tooling services include material, tolerance, volume, and schedule, ensuring the finest fit for specific manufacturing needs.

Is rapid tooling suitable for mass production?

Rapid tooling services excel in prototyping and low to medium-volume production, while conventional tooling practices may prove more economical for mass production.

How does rapid tooling balance speed, cost, and quality?

Rapid tooling employs new processes for making tools quickly and affordably, leveraging rapid production tooling techniques without sacrificing quality too much. It allows manufacturers to strike an equilibrium between productivity and quality.

Can rapid tooling be used with different materials?

Yes, rapid tooling services span a variety of tooling materials, such as plastics and metals. This versatility in rapid production tooling makes it applicable to a wide range of industries.