Key Takeaways

- With on-demand manufacturing, companies can scale up production to meet demand and pull back when demand is low.

- Innovations like 3D printing, cloud manufacturing, automation, and data analytics underpin flexible, bespoke, and agile production processes.

- This model supports low to high volume production, fulfilling small or large orders with equal efficiency as it responds to dynamic consumer demand.

- Software algorithms alone won’t make it happen. On-demand manufacturing requires operational shifts, technology integration and careful partner selection to make processes streamlined and keep intellectual property secure.

- We see the future of on-demand manufacturing being influenced by AI, new advances in materials science, and circular economy ideals–paving the way for more sustainability and agility.

- For companies thinking about making the leap, evaluate existing capacities, retrain your workforce, and take advantage of smart partnerships to capitalize on this emerging mode of manufacture.

On-demand manufacturing is the idea of manufacturing goods when they are required, reducing waste and storage expenses. A lot of companies rely on this to adapt to evolving market requirements and assist with rapid product development.

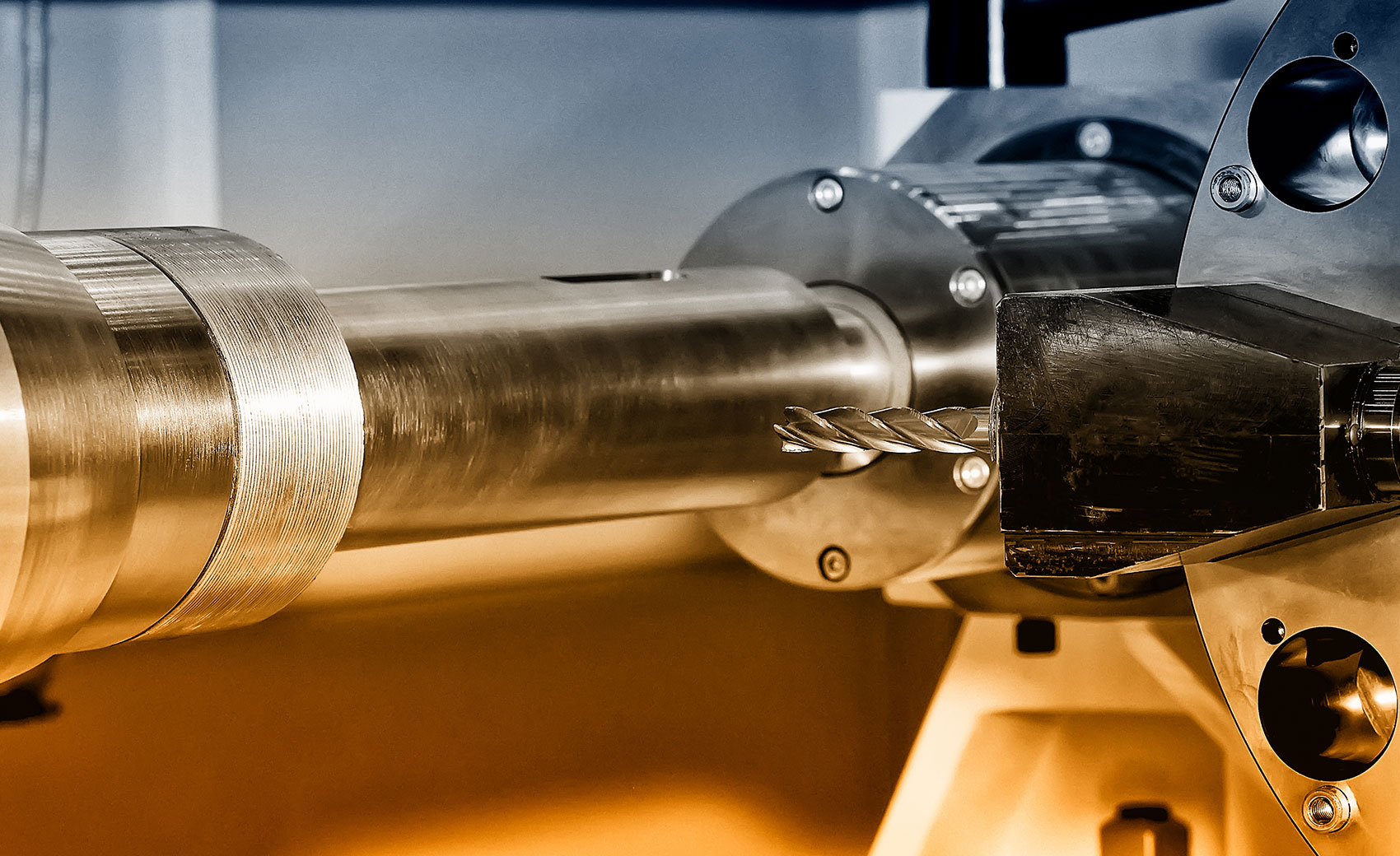

Using on-demand tools such as 3D printing and CNC machines, small batches can be produced rapidly and shipped rapidly. This approach wins in areas such as cars, health care and fashion where it helps satisfy custom orders and short runs.

To take advantage of on-demand manufacturing, businesses typically tap into digital platforms that connect them with vetted producers. The following part will demonstrate these steps in action and highlight what makes this method of manufacturing unique.

What is On-Demand Manufacturing?

On-demand manufacturing, known as manufacturing on-demand (MOD), custom manufacturing, or cloud manufacturing, is a manufacturing approach that creates products solely when a customer requests them. That is, no glut—supply equals demand. It’s powered by agility and productivity, with digital tools and platforms central to enabling it.

It’s employed globally, in numerous industries, to reduce surplus inventory and warehousing expenses while enabling rapid iterations of product designs and production batches.

1. Core Principle

The central concept of on-demand manufacturing is to manufacture products on an as-needed basis. This contrasts with conventional mass production, where businesses predict how much to produce and commonly have surplus goods that might never sell.

When things are made only upon order, it reduces waste and maintains sustainable production. The hazard of overproduction decreases, so materials and power are not wasted on products that gather dust in storage bins.

Customer response is crucial in this arena. Businesses can adjust or modify designs easily because they’re not stuck with large runs. For instance, if a shoe company wanted to tweak colors or fit according to customer feedback it could do so in days.

Rapid prototyping, with the help of things like 3D printing, allows engineers and designers to experiment with new ideas quickly and inexpensively.

2. Key Technologies

Technologies like 3D printing, CAD, and cloud-based software enable on-demand manufacturing. These tools enable businesses to manufacture small batches, or even individual products.

Cloud manufacturing platforms allow factories and teams to collaborate worldwide. This simplifies sharing designs or production jobs when not physically co-located.

Automation, with smart robots and software, accelerates order processing and production. Data analytics identifies issues, monitors patterns and optimizes every phase of the process.

3. Production Spectrum

Whether it’s one custom part or runs of thousands, on-demand manufacturing has no minimum order rules. This agility allows businesses to react to the marketplace quickly, regardless of demand magnitude.

A business can convert its production size as it changes with sales, so there’s less risk of waste. For instance, personalized phone cases or medical devices belong to the on-demand category, whereas standard items with consistent demand remain in the conventional camp.

4. The Digital Thread

This is the digital thread that connects every phase of manufacturing — from creation to completion. This keeps teams informed and allows them to monitor progress through the supply chain.

Digital inventory gives companies visibility of what is required and schedule shipments with less uncertainty. Real-time data fuels rapid, intelligent decisions.

Why Choose This Model?

On-demand manufacturing is quickly becoming the go-to strategy for businesses looking to move fast, save money and deliver to buyers exactly what they desire. This makes data and agility the centerpiece, enabling companies to stay ahead of the world’s changing trends and shrinking budgets.

The model reimagines how products get produced—from unique samples to limited series—through digital technologies and intelligent networks rather than vast storage facilities.

Unmatched Flexibility

Businesses can shift what they produce, and when, based on actual appetite. If a trend shifts, assembly lines shift without breaking stride. That means it’s easy to circumvent extended lead times and deliver orders in days, not months.

Product customization occurs quickly. A company can bring a new design from concept to completed product and get it out the door with minimal turnaround. That goes a long way toward keeping buyers happy, particularly as an increasing number of consumers desire goods customized to their preferences.

On-demand means production can spike or slow with the season, and track shifts in what people are purchasing. There’s less risk—you don’t have to load up a warehouse with inventory that may not move and aren’t forcing capital to sit in dead stock.

Faster Innovation

Companies launch new products at a dramatically faster pace. Digital tools and automated lines allow a designer to have a prototype produced immediately, and receive the outcome within hours.

Fast prototyping wins wait times. Design changes can occur spontaneously, ensuring the product improves with every iteration. This tight feedback loop ensures businesses address issues pronto.

Buyer feedback gets baked into every iteration. That makes products more compelling, and keeps companies a step ahead of competitors. Rapid pivots maintain freshness and allow companies to experiment without major obligations.

Reduced Waste

- Only producing as needed means fewer raw materials used.

- No huge stockpiles that go unsold.

- Lower risk of obsolete products.

- Fewer resources spent on storage space.

Less waste is greener production, which helps the planet. By utilizing a demand manufacturing platform, firms save as they don’t purchase or warehouse more than necessary. Efficient runs keep costs down, enabling you to maintain a lean and sustainable business.

Cost Dynamics

|

Cost Factor |

On-Demand |

Traditional |

|---|---|---|

|

Inventory Holding |

Low |

High |

|

Facility Maintenance |

Minimal |

Substantial |

|

Upfront Investment |

Lower |

Higher |

|

Flexibility |

High |

Low |

New ways slash the requirement for bulky, underutilized plants, as demand manufacturing platforms allow companies to scale output on-demand while maintaining slim inventories. By grasping these expenses, decision-makers can make intelligent decisions that align with their organizational objectives.

On-Demand vs. Traditional

On-demand and traditional manufacturing processes both have their strengths. Enterprises compare these manufacturing models according to their requirements for agility, flexibility, and price, with demand manufacturing platforms offering operational efficiencies.

|

Feature |

On-Demand Manufacturing |

Traditional Manufacturing |

|---|---|---|

|

Production Flexibility |

High |

Low |

|

Lead Time |

Short |

Long |

|

Inventory Requirements |

Low |

High |

|

Customization |

Easy |

Challenging |

|

Initial Setup Cost |

Low-Moderate |

High |

|

Scalability |

Moderate |

High |

|

Response to Demand Change |

Responsive |

Rigid |

Production Volume

Production volume typically influences the choice between the two. On-demand manufacturing loves short runs or even singletons, leveraging 3D printing or CNC machining to churn through work orders with speed. It’s perfect for markets with volatile demand.

Traditional setups grind out massive, redundant orders. Factories are able to churn out thousands at a time, with dedicated lines. Mass manufacturing implies large commitments, and errors can result in surplus inventory.

On-demand’s greatest advantage is in small, or custom orders. Such orders may be launched as soon as demand arrives, saving inventory costs. For short runs, the unit cost might be higher in the near term, but it’s usually cheaper than tooling up an entire old-school line for a small run.

Supply Chain

On-demand manufacturing employs agile supply chains. Demand spikes or dips, it scales. Cloud-based tracking and digital tools assist to update orders on the fly, and less inventory reduces risk.

Traditional supply chains are less agile. They must predict, purchase, and warehouse huge quantities, which risks loss if demand changes. On-demand approaches eliminate the risk of overproducing, but they make supplier reliability key.

On-demand vs. Traditional, a missing material can stop production fast!

Product Lifecycle

So on-demand manufacture shrinks the lifecycle. New styles or features can be introduced rapidly, allowing companies to react to consumer demand. Traditional manufacturing locks in long cycles, with big batches that require months to sell.

On-demand’s value comes from being able to test, learn, and revise. Consumer input drives the next cycle, resulting in a better fit for shifting requirements. This cycle is significantly more difficult to realize with traditional approaches, where design modifications equate to new tooling and increased capital.

Initial Investment

On-demand manufacturing demands less up front capital, with flexible systems and modular equipment. On-demand companies can start small and scale with demand.

Traditional manufacturing requires expensive investment in dedicated lines—often millions of euros per plant. Flexible systems pay for themselves by reducing waste and increasing agility.

The ROI escalates as companies sidestep overproduction and pivot to new trends.

The New Manufacturing Mindset

On-demand manufacturing represents an unmistakable pivot away from inflexible mass production toward nimble systems designed for velocity, transparency and scalability. The fundamental concept is to produce what’s required, when it’s required, leveraging technology and information to stay ahead of demand.

This mindset still wants companies to shake up old routines, prioritizing customization, transparency and just-in-time inventory. It’s a direct reaction to worldwide supply chain issues and the broader necessity to be less dependent on centralized factories. New tools such as 3D printing, CNC machining and cloud-based software lie at the center of this transformation.

Democratizing Creation

On-demand manufacturing gives individuals and small teams the ability to create products that previously required large budgets and factories. You no longer have to own a massive warehouse or assembly line to create a new part or product.

You simply require an entrée to the appropriate stage. This transition implies that a larger number of individuals are able to take concepts to market quickly. Makers, students and startups can now design and order parts in hours using services like 3D Hubs or Xometry.

Availability of these tools ignites more innovation and competition, because the barriers are so much lower. Platforms are linking creators to factories and consumers, opening up the process to anyone.

Data as a Blueprint

Data is now the compass for each step of on-demand manufacturing. It’s like UPS tracking, but for your order flowing through every step — companies can see it in real-time to ensure nothing falls behind.

Data decisions help determine what to make, when, and how much, which keeps carrying costs and waste low. Analytics allows makers to adjust products in real time. If a batch isn’t selling or a part breaks frequently, they can repair issues quickly.

Data-informed design—whether it’s simulating or user feedback—allows for products that are customized per purchaser. Ultimately, data makes the entire system smarter, faster and more responsive to human desires.

From Product to Service

Today manufacturers don’t just sell stuff—they sell service as well. Rather than simply shipping goods, many offer continual support, repairs or even upgrades upon request.

That way, businesses access new revenue streams, such as premium add-ons or subscriptions. Technology, like cloud software or IoT sensors, lets them run these services with less friction.

Service-based models allow firms to pivot quickly in fluctuating markets, resulting in deeper, enduring customer relationships.

Navigating the Transition

Transitioning from traditional to on-demand manufacturing is not merely a matter of plugging in new tools. It’s a change in mindset, workflows and relationships. Companies have to reconsider how they manufacture, warehouse and distribute.

The shift is urgent—long lead times and misaligned inventory make it impossible to capture actual demand. On-demand manufacturing reduces lead times, aids businesses in alignment with customer desires, and minimizes waste.

-

Assess current capabilities: Companies must first review their existing equipment, processes, and workforce skills. This allows clear identification of gaps between current practices and the demands of on-demand production.

-

Define needs and targets: Understanding specific market demands and the expected scale of production is essential. That means identifying whether the business will facilitate tiny, custom orders or more generous, loose runs.

-

Upskill employees: Training staff in digital design, data analytics, and advanced production tools like 3D printing or CNC machining is crucial.

-

Integrate new technology: Adopting AI, IoT, and advanced analytics systems improves real-time monitoring and decision-making.

-

Build strategic partnerships: Collaborating with external on-demand service providers or technology experts can speed up the transition and fill gaps in expertise.

-

Protect intellectual property: With more collaboration, companies must safeguard designs, data, and innovations.

-

Continuously improve: Regular review of processes and outcomes ensures ongoing adaptation and efficiency.

Operational Shifts

Shorter supply chains are a big shift. Legacy systems can require as long as ten months to deploy, whereas on-demand infrastructures accelerate this process. That’s no more guessing how much to make or risking mountains of unsold inventory for companies.

Making the switch demands fluid workflows. Production lines must pivot at a moment’s notice–to enable, in some cases, a shift from one-off jobs to extended runs. Technology is crucial in this regard. Solutions such as IoT sensors monitor quality at the moment.

AI assists in identifying problems prior to them inducing waste. 3D printing and CNC machines provide rapid, customized output. Continuous improvement ain’t a one-time thing. Frequent review of data — and feedback from both staff and customers — helps identify weak spots and adjust processes.

This helps keep operations lean and nimble as market demand changes.

Partner Selection

Opting for a partner for on-demand manufacturing is a big decision. Seek partners with tried-and-true technology, excellent data security, and a history of sticking to timelines. It’s not just price—trustworthiness and clarity count more in rapid markets.

Team work is essential. A great partner works shoulder to shoulder – sharing mastery and adapting quickly. This assists organizations stay upfront and reduce errors.

Robust relationships unlock new manufacturing capacities, enabling companies to accept more diverse orders and access untapped markets.

Intellectual Property

IP protection is key in on-demand manufacturing. There’s danger in sharing designs and prototypes with partners—leaks can sap market advantage. Businesses require contracts, strong digital security and frequent audits to maintain their IP.

These best practices cover everything from secure file transfer tools to watermarking designs to legal contracts that spell out ownership and use rights.

The Future of Production

On-demand manufacturing is revolutionizing the production and distribution of products. It slashes waste, injects flexibility, and lets companies pivot quicker. As increasing numbers of companies adopt digital tools and smart systems, the future of production will differ significantly from what we’ve seen in the past.

Key elements driving this change include:

- Smart automation and robotics in factories

- Widespread use of 3D printing and CNC machining

- Digital inventories for real-time production

- AI-driven demand forecasting and scheduling

- Focus on sustainable processes and materials

- More local, distributed manufacturing hubs

- Partnerships between industry and education for workforce training

AI Integration

AI makes factories smarter. It can read demand signals, anticipate when machines require repairs, and assist in planning production schedules. This leads to less time down and fewer back-ups.

AI also handles inventory; it cuts overstock and shortages. It aligns raw materials with orders as they arrive, ensuring no waste. Additionally, AI inspects products for defects with cameras and sensors, detecting issues quickly. This makes quality control more rapid and reliable.

In the future, AI might design products, identify emerging trends, or recommend more efficient production methods.

Material Science

Material science is powering the advent of on-demand production. New plastics, resins, and metals pair nicely with 3D printers or CNC machines. These resources assist firms in experimenting with new offerings sans massive initial expenses.

For me, better materials translate into better products. Lighter, stronger, or recyclable alternatives are now available. This allows companies to comply with rigorous waste and safety regulations.

Research groups across schools and corporations experiment with methods of making substances more durable or safely degradable. More courses now train practical skills for dealing with these sophisticated materials.

Circular Economies

A circular economy is about perpetually using resources, not singly. On-demand manufacturing maps to this paradigm by producing just what’s necessary and slashing surplus inventory. It assists in keeping waste minimal and facilitates recycling.

Closed-loop systems imply that old parts have the potential to be used again in new products. Companies can engineer products to disassemble at end of life so components can be reclaimed.

In this manner, factories consume less raw materials and give less to landfills. Do these, and corporations can both save cash and save the earth.

Conclusion

On-demand manufacturing is special because of the speed and fit. Makers can slash waste, ship orders quickly, and maintain lean inventory. Small shops and big brands alike reap the rewards. Companies turn away from slow, big runs to fast, clever moves that fit true demand. A lot of them now leverage local shops or digital tools to construct components. The old ways don’t impede people who want to experiment or patch supply chain holes. The path to this model can demand new expertise, yet the reward reflects itself in price, speed, and reduced waste. To explore real-world examples or contact us with questions. The greatest partnerships begin with great ideas and great conversation.

Frequently Asked Questions

What is on-demand manufacturing?

On-demand manufacturing platforms facilitate the creation of products precisely when needed, minimizing surplus stock and waste while supporting effective production and customization for quicker time to market.

How does on-demand manufacturing benefit businesses?

On-demand manufacturing platforms save businesses money by reducing inventory costs, minimizing waste, and maximizing flexibility. These demand manufacturing technologies enable businesses to be agile in meeting customer demand and market shifts.

How is on-demand manufacturing different from traditional manufacturing?

Traditional manufacturing often leads to inventory surplus, while a demand manufacturing platform produces items only as needed, enhancing customization and reducing inventory costs.

Is on-demand manufacturing sustainable?

Right on, the demand manufacturing platform is more sustainable as it minimizes over-production, resource usage, and waste, making it more environmentally friendly than traditional manufacturing methods.

What industries use on-demand manufacturing?

A lot of industries utilize a demand manufacturing platform, such as fashion, automotive, electronics, and healthcare. It’s particularly popular in sectors where rapid production and personalization are essential.

What are the challenges of switching to on-demand manufacturing?

Transitioning to a demand manufacturing platform can necessitate new technology, supply chain alterations, and employee training. Companies must strategize accordingly to keep the transition seamless and ensure effective production.

Will on-demand manufacturing replace traditional methods?

On-demand manufacturing platforms are taking off, but they don’t replace traditional manufacturing methods. Each has its advantages, and most companies employ a combination to address different production processes and markets.