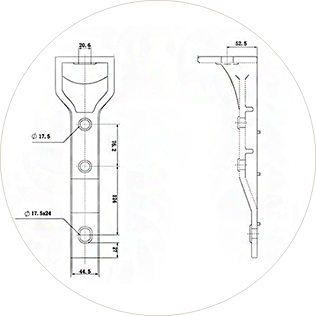

OEM Gray Iron Casting Auto Accessories Vehicle Components Customized Tractor/Auto/Automobile/Automotive Part

Enquire Now*Provide your application requirements—such as stress conditions, materials, size range, and even product name. We are always available for customization, so please contact us directly.

Specifications

Name OEM Gray Iron Casting Auto Accessories Vehicle Components Customized Tractor/Auto/Automobile/Automotive Part Material Iron. Gray iron 200/250;/300/350.Nodular cast iron 400/450/500/600/700 Process Sand Casting, Shell Casting, Deburring, Sandblasting, Machining, Heat Treatment, Leakage test, Surface treatment, etc Machining equipment CNC, Lathe machine, milling machine, drilling machine, grinding machine Lead time Depending on the structure and size Material standard ISO, GB, ASTM, SAE, ISO, EN, DIN, JIS, BS Applicable Industry Automotive Parts, Railroad Parts, Marine Parts, Lighting Parts, Pump Body, Valve Parts, Architectural Parts and Furniture Parts Surface treatment Powder coating, Chrome plating, Painting, Sand blasting, Nickel Plating, Zinc Plating, Blacking, Polishing, Bluing, etc Quality Control 100% QC Inspection Precision or Not High Precision Specification Customized Trademark As customer request Packing Carton, Pallet, Wooden Case, Steel Case, Iron Case Cast iron is a common casting material, its main components are iron, carbon and silicon. Cast iron has good fluidity, wear resistance and corrosion resistance, and is widely used in machinery manufacturing, construction engineering, automobile manufacturing and other fields.

Process of cast iron:

1. Mold manufacturing, according to the shape and size of the casting mold, divided into sand, metal, ceramic and other types.

2. Smelting, using blast furnace smelting, reduction reaction, tempering treatment.

3. Casting, control the casting temperature and speed to ensure the compactness and surface quality of the casting.

4. Cooling, natural cold sweat or water cooling.

5. Clean and remove the oxide and sand on the surface of the polished casting.

6. Inspection, inspection of appearance, size, chemical composition and mechanical properties.

Related Products

Do you accept small orders?

Absolutely. Our minimum order quantity is 1 piece. You can order a small amount to feel the high quality of our products!

How long is your product warranty?

We offer a 2 years warranty on all our products

What’s your typical lead time?

Lead time depends on part complexity and order volume. For most prototypes or low-volume runs, we offer lead times as fast as 5–7 working days. Rush orders can often be accommodated.

Can I request a sample?

Yes. For Electric Power Fitting, we can provide first article samples upon request. Whether it’s sheet metal, CNC-machined, or assembled parts, we offer sample production to help you evaluate form, fit, and function before moving into full production.

What if the size does not match at the installation site?

We support customized service, in case of size inconsistency, you can contact your account manager at the first time. We will assist in confirming the cause of the problem and provide solutions such as modifying drawings, re-processing or replacing parts to ensure smooth installation of the product and reduce your time and cost loss.

How do you solve the problem of high mold cost and long delivery time?

We provide a variety of low-cost, fast delivery solutions, fusion molding, sand casting, disappearing mold, aluminum mold fast mold, mold sharing mechanism, as well as long-term cooperation mechanism with mold factories, to ensure that the opening of the mold is fast, save money, and do not affect the quality. For trial orders and small batch orders, we also offer flexible development programs to minimize the risk of upfront investment for our customers.

Do you provide type test reports or third-party certifications (e.g., IEC, ANSI)?

Yes. We can provide type test reports and third-party certifications upon request, especially for projects requiring compliance with IEC, IEEE, or national grid standards.

No Drawings? No Problem.

*With 25 years of experience, we help manufacturers worldwide turn “standard problems” into custom solutions.

sketch design stage

You only need to provide a sample or basic dimensions — our engineers will handle the rest. We turn your ideas into precise technical drawings based on a deep understanding of your actual needs, ensurinYou don’t need to prepare a full 3D model or detailed drawing.

3D modeling and production stage

We build high-precision 3D models based on the initial design, verifying every detail with professional software to meet production standards. Once approved, we move straight into precision manufacturing.

Testimonials

FERR always puts the interests of its customers first.

Yunex

Distribution network project contractors in Southeast Asia

I was most afraid of the drawings sent over to the docking is not clear, the results of FERR engineers directly with me to dock the technical details, and even the bolt hole spacing are confirmed to be very fine. Proofing out once through, no rework, too much trouble.

Orlando J.

Equipment distributors in Europe

Our customers are very picky, especially about the thickness and appearance of the hot-dip galvanized layer, and the goods sent by FERR not only meet the standard, but also the key is that each batch is very stable, and we have never had any problems with the secondary inspection.

Lambrinie

Procurement Manager, X Power Engineering, USA

We started out with just a couple samples to try, and they turned out to be so much better than what we were using before. The dimensional accuracy, surface finish are all spot on and the delivery was fast. Now every time I have a project I go to FERR first, with confidence.

Marco Martinez

Project Manager in the Middle East

I've used quite a few suppliers, some quotes are cheap but with lots of problems.FERR is not the cheapest but they are really the most hassle free. Design coordination, delivery time, packaging details can think ahead of me, I save a lot of energy.