One-Stop Precision Machining Services Manufacturer

Precision Machining Services

Start A New Quote

Start to Upload Your Files

Start to Upload Your FilesSTEP STP SLDPRT IPT PRT SAT IGES IGS CATPART X_T OBJ STL files

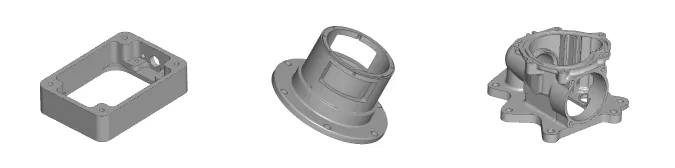

Focus on Precision Machining Parts

Our Precision Machining Parts Are Engineered to Meet the Demanding Requirements of Applications Worldwide. to discuss your project requirements. Get in touch to discuss your project

Precision CNC Machined Ship Parts

Medical Equipment High Precision Component Aluminum CNC Machining Parts

Professional CNC machining of impeller parts

Custom Metal CNC Machining Flange Components

CNC High Precision Metal Machining – Machine Tool Parts

Aluminum CNC Precision Machined Aluminum Alloy Housing

I don't have complete drawings, can I send inquiry?

Yes, we can help you analyze based on your description, samples and photos.

I am not sure if you can do my parts?

Most of our customers come to us because “others say they can’t do it”.

Are you a factory or a trader?

We are a factory and have a project management team that can handle the technology, cost and delivery at the same time.

What is Precision Machining ?

Precision CNC machining uses computer-controlled tools to produce highly accurate parts with consistent quality.

This process enables precise control over every feature—size, shape, and tolerance—making it ideal for complex geometries and parts that require precise fit and function.

With precision CNC capabilities, industries can achieve tight tolerances, smooth surface finishes, and repeatable accuracy across prototypes and mass production.

This ensures each component performs reliably in its application, whether it’s part of machinery, electronics, or custom assemblies.

Our precision machining services

Choosing the right forging method directly impacts strength, cost efficiency, dimensional stability, and production feasibility.

Grinding Service

Ideal for axial and radial load-bearing ring-shaped components, such as flanges, gear rings, bearing races, couplings, and wind/railway rings. Produced without welds or joints, resulting in continuous grain flow and superior fatigue life and impact resistance.

CNC Turning Service

Best suited for large-size, low-volume, heavy-duty, or shape-flexible components such as shafts, cylinders, blocks, and gear racks. Offers dense internal structure, customized dimensions, and broad industry adaptability.

CNC Milling Service

Designed for medium-to-high-volume production of strong, complex-shaped parts, including lifting hardware, automotive components, and construction machinery fittings. Provides high repeatability, high material utilization, and enhanced mechanical strength through precision die tooling.

Precision CNC Machining Tolerances

Use the tolerance ranges below to determine whether your part falls within the capabilities of CNC milling, turning, or grinding — or if enhanced precision steps are necessary.

Category

Typical Tolerance (mm)

Best Possible Tolerance (mm)

Notes

CNC Milling

±0.025 – ±0.10

±0.005 – ±0.01

Precision varies with tool size, material, and machine rigidity. Ideal for 2D/3D shapes.

CNC Turning

±0.01 – ±0.03

±0.005 – ±0.01

Excellent for round parts requiring high concentricity and smooth finish.

Grinding

±0.005

±0.001

Provides the best surface finish. Used for tight-tolerance surfaces and final passes.

Our CNC Manufacturing Approach

Our CNC process focuses on accuracy, consistency, and repeatability. By controlling every step—from material preparation to machining strategy and final inspection—we ensure each part meets its required tolerances and functional performance.

Material Selection & Preparation

We work with a wide range of metals—including carbon steel, alloy steel, stainless steel, aluminum, and brass—ensuring each material meets required hardness, machinability, and dimensional stability before cutting.

CNC Programming & Machining Strategy

Parts are programmed with optimized tool paths based on geometry, tolerances, and surface requirements. Cutting parameters are adjusted to control heat, reduce tool wear, and maintain accuracy for both 2D and complex 3D shapes.

Precision Machining & Surface Control

Multi-axis milling and turning operations achieve tight tolerances, consistent dimensions, and smooth finishes. Secondary steps such as drilling, tapping, deburring, or surface refinement are performed as needed.

Quality Inspection & Verification

Finished components undergo dimensional checks using calipers, gauges, and CMM when required. Surface finish, run-out, concentricity, and thread accuracy are validated to ensure every part meets specification.

Advantages of Our Precision Machining Services ?

Precision machining enables manufacturers to produce parts with high accuracy, stable quality, and tight process control. For applications that demand reliability, repeatability, and precise fit, this method offers clear advantages.

Secondary Operations and Treatment of Precision Machining We Offer

Applications of Precision Machining

Precision CNC machining supports a wide range of industries that require accurate, reliable, and application-specific components, such as:

Engine Components

Precision-machined shafts, housings, and powertrain parts with stable performance under heat and load.

Electronics Parts

High-accuracy connectors and small components for reliable fit, assembly, and electrical performance.

Aerospace Fasteners

High-strength fasteners and small structural components machined with tight concentricity and stable accuracy.

Tool and Die Making

Durable, high-precision tool steel components that ensure consistent output in mass production.

How to Work With us

Provide 3d drawings

Evaluate the quotation

Manufacturing

Order delivery

Get 3-day standard lead times on simple parts between 10 mm x 10 mm and 200 mm x 200 mm. Upload your part to see if it’s eligible.

Frequently asked questions

Drawing evaluation: 1-2 business days

Prototype production: 5-10 business days

Small-batch production: 10-15 business days

Large-scale production: 15-30 business days

Rush service: 72-hour rush service available (additional fees apply)

We have established a comprehensive quality management system:

ISO 9001:2015 Certification: International quality management standard

First Article Inspection: 100% confirmation of the first piece before mass production

Process Control: 100% inspection of critical processes

Finished Product Inspection: Full dimensional inspection using CMM coordinate measuring

Quality Traceability: Complete production and inspection records

We support both small-batch prototyping and large-scale production. MOQ starts from as low as a few dozen pieces, and high-volume orders up to hundreds of thousands are welcome.

Yes. Besides producing according to drawings, we provide DFM (Design for Manufacturability) support to reduce costs and improve efficiency.

Pricing is based on material, process complexity, order volume, and delivery requirements. We aim to offer the most cost-effective solution for every project.

We serve automotive, machinery, electronics, medical devices, and energy sectors. From precision parts to structural components, we have extensive expertise.