Key Takeaways

- Large CNC machining is critical for industries like aerospace, energy, and heavy equipment, where it’s used to create exceptionally precise, large-scale components that would be impossible with conventional methods.

- Machining oversized parts requires specialized machine architectures, including gantry mills and boring mills, as well as specialized tooling and material selection to achieve quality results.

- Digital tools — from sophisticated CAM software to simulation and real-time monitoring — remain critical for process optimization, waste reduction, and accuracy at scale.

- Rigorous quality control, leveraging metrology tools and thermal compensation, is vital to achieving tight tolerances and industry standards, particularly considering the distinct challenges posed by manufacturing large parts.

- Well-thought out logistics – such as facility space and handling equipment – must be in place to assist in the safe transport, installation and flow of operations for large CNC machining projects.

- Big CNC machining investment pays off big time with efficiency, quality and competitive advantage, but demands big upfront and operational spend that has to be carefully managed.

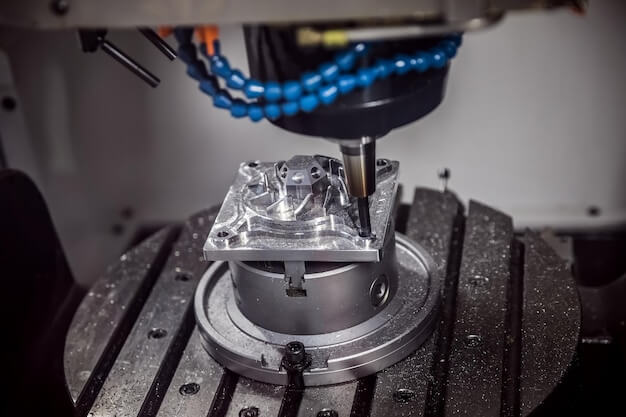

Large CNC machining applies computer-controlled tooling to high-precision fabrication of large or heavy components. These machines process metals, plastics and composites for work in industries such as aerospace, energy and transportation.

Large CNC shops frequently rely on gantry mills or vertical lathes to carve out, bore, and form pieces spanning several meters in length or width. Large work tables and powerful spindles enable them to maintain tight tolerances even on gigantic workpieces.

Several teams employ 3D models to setup jobs and validate quality with in-process sensors. Large CNC machining assists in reducing expenses, minimizing manual mistakes and accelerating the manufacturing of bespoke and/or intricate components.

Read on below for more about tooling, workflow and the core use cases.

Defining Large CNC Machining

Large CNC machining is essential for the computer-controlled machining of big parts or heavy components, typically exceeding one meter in length. This specialized machining service is crucial for industries requiring scale, precision, and expediency. It effectively meets the large machining needs that traditional machining tools cannot fulfill, especially when dealing with oversized components.

Industries such as aerospace, energy, marine, automotive, and construction rely on large part machining to produce turbine housings, windmill hubs, ship propellers, and massive engine blocks. The challenges of size, material, and logistics necessitate a tailored approach, where precision at scale is a hallmark of the machining process.

1. Beyond Size

Large CNC machining is about more than just large parts; it encompasses challenging machining tasks that arise with large workpieces. These issues include part schlumping, vibration, and complicated fixturing. The machine structure itself is crucial—a rigid base and special bellows covers help reduce tool wear and control tolerance stacking errors, especially in the realm of heavy machinery.

The work envelope may seem large on paper, but actual boundaries are defined by the cutting tools, spindle reach, and fixturing. For instance, a machine qualified for 3,000 mm parts might still require special configurations to operate optimally, especially for large machining needs.

This is where high-end five-axis CNC technology steps in to assist, incorporating two additional rotation axes. This advancement allows shops to efficiently produce complex shapes on large parts with minimal downtime, enhancing their overall machining operations.

2. Material Challenges

Machining large parts from titanium or aluminum is hard. Titanium’s hardness can reduce tool life and create heat, while grades like 6061-T6 or 7075-T6 aluminum provide a speed/yield strength equilibrium. Selecting tooling—like insert cutters or carbide mills—is key as tool deflection and chatter increase with part size.

Deep cavities and undercuts should be minimized — they slow production, bend tools, and require more complicated workholding. Material characteristics influence tactics. High-strength alloys may require slower feeds, while softer metals enable faster cuts but are prone to chatter.

Each option alters the cycle time and the finish. For big jobs, the right tooling and material mix can be the difference between a slick job and an expensive back-up.

3. Logistical Hurdles

Handling, moving and storing massive workpieces introduces genuine logistical challenges. Shops must have cranes, forklifts and ample room to navigate parts without harm. Large workpiece machines consume more floor space and require reinforced foundations, thus planning begins well before the initial cut.

Large workpieces frequently require custom or modular fixtures. These secure parts in place and allow the operator to access all sides with minimal repositioning. To streamline workflow is to keep tools and setups close, map out every move, and digitally track materials.

4. Precision at Scale

Maintaining tight tolerances on a three meter part is difficult. Even minor blunders can add up. Shops employ sophisticated metrology equipment—such as laser trackers or CMM arms—to verify dimensions in-process.

Key tactics involve sectioning big parts into smaller sections for inspection and employing temperature controls to minimize material shifts. Maintaining precision on your large parts translates to improved fit, extended longevity and less defects.

That’s why industries rely on large CNC machining for mission-critical parts.

Core Machine Architectures

Large CNC machines are designed with various core structures that cater to heavy machinery, precision, and large parts CNC machining needs. The architecture of each machine type significantly influences its strengths, speed, and position within a machining process workflow, ensuring efficient handling of challenging machining tasks.

|

Machine Type |

Key Features |

Typical Applications |

|---|---|---|

|

Gantry Mills |

Gantry x-y motion, high rigidity, wide travel |

Aerospace frames, shipbuilding, tooling |

|

Boring Mills |

Horizontal spindle, large part support, precise boring |

Energy, automotive, heavy equipment |

|

Machining Centers |

Multi-axis (3-5+), tool changers, automation |

Prototyping, production runs, complex parts |

Gantry Mills

Gantry mills feature a bridge structure and utilize a gantry x-y motion system, which allows the tool to move along both axes with precision. This architecture enables the machinery to carve out complicated, round, or angled paths, as well as simple straight ones. Gantry mills excel in handling large parts machining needs, especially for oversized workpieces or heavy plates found in aerospace or energy sectors.

These generalized machines are constructed to handle a variety of substances, pivoting from slicing aluminum to hard steel or even composites with minimal setup changes. Their open architecture accommodates various cutting heads and attachments, making them a favorite among shops that frequently switch jobs, particularly for challenging machining tasks.

The gantry’s rigid frame minimizes vibration and enhances cut quality. This stability is crucial for maintaining tight tolerances across huge spans—something that smaller machines or less massive designs simply can’t achieve, especially during high horsepower machining operations.

For massive pieces, such as crafting airplane frames, windmill molds, or ship panels, gantry mills are often the go-to choice. They provide an excellent machining capability, offering a mix of reach, power, and repeatability that is essential for large machining projects.

Horizontal Boring Mills

Horizontal boring mills have a spindle that runs parallel to the floor, which enables them to bore, drill, and mill parts that are large, heavy or awkwardly shaped. Their long tables and deep travel distances can accommodate bulky workpieces, such as engine blocks or machine bases, that wouldn’t fit on other machines.

They’re popular because they could machine complex internal features. Multi-axis boring mills can integrate boring, facing, and contouring in a single setup — speeding up the process and increasing accuracy for complex components.

On these high volume runs, these mills keep cycle times down. Their structure and rigid mounts enable aggressive material removal — essential for churning out large batches of heavy components.

Power generation, mining, and construction equipment are just some of the industries that depend on horizontal boring mills for their big, weird parts—turbine housings, pump bodies, gearbox cases.

Large Machining Centers

Big rigs like large machining centers are the muscle of flexible high-mix manufacturing. They may be three, four, or five axes, and sometimes more, which allows them to efficiently handle large parts CNC machining needs. This capability enables them to process compound contours or even merge lathe and mill functions in a single pass. Long travel—sometimes several meters—means they can machine parts much larger than traditional equipment.

These cores combine many machining operations. Operators have the ability to mill, drill, tap, and even finish parts in one setup, which translates into less jumping in and out of machines. This reduction in configuration times minimizes mistakes and accelerates turnaround, making them ideal for challenging machining tasks.

Automation is huge in modern CNC machining. Automatic tool changers, probing systems, and programmable workholding allow a machining center to run longer without pausing. This efficiency enables companies to meet hard deadlines or bootstrap production with fewer workers, addressing immediate machining requirements.

Machining centers are notable for their versatility. They can turn a batch of wind turbine components into a custom aerospace tool with a quick program and fixture change. This flexibility is why they’re ubiquitous in job shops and the contract machining industry.

Design Impact on Performance

The form, number of axes, and stiffness of a machine determines its capabilities. More axes allow shops to machine complex, curved, or angled components without having to flip the part and/or reset the job–saving time and increasing precision.

The deeper the travel, the bigger workpiece you could deal with. Maintaining vibration low and rigidity high is imperative. This is why frame design and spindle support are essential.

Multi-axis configurations minimizes the number of setups and eliminates error, while spindle power and tool size determine cutting speed and depth. The work-area-to-machine ratio matters: routers suit large, thin sheets, while mills are better for tall or thick blocks.

Restrictions like the 2:1 diameter ratio or tap size limitations dictate what can be produced in a single operation.

The Digital Backbone

Digital is now at the heart of big CNC machining, defining how parts are manufactured, inspected and optimized. Software, sensors and data all combine to increase velocity, reduce errors and minimize expense. These tools provide CNC machining with the versatility to accommodate all sorts of jobs, from one-off prototypes to mass production.

As digital systems improve, they assist factories to produce more consistent components and create new career opportunities for those in machine operation, programming, and quality assurance.

Advanced CAM

CAM software is a crucial component of our digital backbone for CNC machining technology. Today’s CAM software not only reduces setup times but also prevents errors during programming, which is essential for high-quality machining services. By effectively handling intricate tool paths, it ensures that machinery operates at the proper spindle speed and cutting force.

For example, when tool paths are optimized for large parts machining needs, a machine can complete a complex mold more quickly and with less tool wear. Most CAM systems now work directly from CAD files, facilitating a seamless transition from design to the machining process without the need for redrawing or file translation, thereby eliminating potential mistakes.

Additionally, CAM allows shops to experiment with various cutting strategies, such as adaptive clearing or high-speed machining, before executing the job on an actual workpiece. This capability makes CAM indispensable for shops aiming to produce consistent, superior machining results at scale.

Simulation Software

Simulation software allows machinists to test runs in a virtual environment before a single part is cut. Armed with these tools, teams are able to identify conflicts, incorrect configurations or inefficient actions that would otherwise consume time and material.

For big CNC work, that’s particularly crucial as errors on big, expensive blanks can translate to massive losses. Most simulation software displays a digital twin of the machine and workpiece, so teams can observe the entire process from beginning to end.

This assists in training young operators, as they can practice on virtual controls before rocking a real rig. By modeling the entire operation, stores maintain low overhead, minimize waste and ensure projects execute correctly the initial time around.

In-Process Monitoring

Today’s CNC machines implement real-time monitoring, checking their own work on the fly. Sensors embedded in the machines monitor variables such as cutting force, vibration, and temperature. If the data indicates that something is amiss—perhaps a tool is becoming worn—machines can decelerate or halt production to prevent the creation of defective parts.

This amount of control equals less downtime and fewer mistakes. Shops may even be able run jobs overnight or with less people on site, confident that the system will notify them if there is a problem.

For large-scale work, where every error costs you, in-process monitoring is a godsend. It helps comply with stringent quality standards, as each cut is monitored and logged.

Digitalization and the Future

Digital tools just keep enhancing CNC shops, particularly in the realm of large parts CNC machining needs. Software upgrades, smarter sensors, and new ways to use data mean shops can keep up with new trends and immediate machining requirements.

Ensuring Quality and Precision

Large CNC machining involves guaranteeing that every part meets precise specifications for dimensions and surface finish. Maintaining quality and precision is more than good business—it’s critical for complying with industry regulations, security requirements and performance objectives.

That is, employing rigorous trials, intelligent instruments and techniques to detect errors during their nascent stages and maintain each component at an optimal level of accuracy.

Metrology Tools

|

Tool |

Purpose |

|---|---|

|

Coordinate Measuring Machine (CMM) |

Measures 3D geometry with high accuracy for complex parts |

|

Laser Scanner |

Captures millions of surface points quickly for detailed inspection |

|

Surface Roughness Tester |

Checks texture and smoothness for compliance with finish specs |

|

Calipers & Micrometers |

Fast checks of simple dimensions and features |

|

Optical Comparator |

Projects part silhouette to compare against tolerance profiles |

CMMs are the workhorses of most quality control labs. They inspect intricate forms and close tolerances — sometimes in runs of thousands. Their automated probes and digital readouts mean less room for human error, which is crucial in parts where a few microns make all the difference.

Laser scanners take it a step further, mapping surfaces rapid-fire—millions of points in seconds—to detect minuscule imperfections or warping that can be overlooked by touch probes. Tight tolerance checks may use the aforementioned techniques, such as tactile scanning or optical metrology, particularly for parts in aerospace or health care, where one out-of-spec feature can mean failure in the field.

Thermal Compensation

Thermal effects can twist or swell large machined parts, skewing measurements by tenths of a millimeter and beyond. This stuff is a big deal for hot-running parts or for shops where temps swing.

Smart CNC’s monitor temperatures at the spindle, work piece and even the room, and then apply compensation tables to tweak tool paths in real-time. Certain shops employ coolants or climate control to help maintain consistent temperatures, but material selection is important as well — utilizing alloys with low thermal expansion can mitigate risk prior to that initial cut even beginning.

Surface Finish

The finish of a part’s surface isn’t merely aesthetic. In certain industries, a polished surface shaves friction, halts corrosion and aids in sealing in assemblies.

Machinists grind and polish and sometimes even treat chemically to achieve global spec finishes like Ra (roughness average) in micrometers. Each batch is tested—surface testers glide across the face to verify the texture is on target.

The best shops record these numbers, associating each outcome to a particular machine, operator, and lot for traceability.

Key Industry Applications

Large CNC machining defines key industry applications by enabling the production of large, complex, and extremely precise parts. Its span extends through multiple industries, with their unique demands and criteria. CNC machining increases efficiency, achieves precise tolerances and enables industries to keep pace with increasing demand for intelligent, more durable products.

Primary industries using large CNC machining:

- Aerospace

- Automotive

- Energy (renewable and non-renewable)

- Heavy equipment (construction, mining, agriculture)

- Marine

- Medical devices

- Defense and firearms

- Music instruments

Aerospace

Large CNC machining is critical in the aerospace industry, where everything from fuselage frames to landing gear depends on tight tolerances and repeatable quality. Aerospace components can span multiple meters and utilize high strength metals such as titanium or aluminum alloys.

These sections have to adhere to worldwide aviation specifications, so even the smallest defect can cause failure or refusal. This industry requires components that endure both intense pressure and thermal fluctuations.

The work is often on five-axis machines, which can cut and shape from multiple directions, allowing designers to produce lighter, stronger parts that would be impossible with older tools. New toolpath simulation and probing improvements maintain error rates while accelerating inspections, getting businesses to their challenging delivery targets.

Energy Sector

The energy sector — wind, hydro, oil, and gas — relies on large CNC machining for components including turbine housings, generator frames, and pressure vessels. These elements can be a few tonnes heavy and extend beyond two meters, so precision is crucial to reliable function and durability.

Even small blemishes can give rise to a shutdown or safety hazard. Renewable energy like wind depends on massive, accurately machined gearboxes and rotors, and oil and gas fields require bespoke, heavy-duty wellhead parts and pipeline supports.

Machining these large pieces is hard because they’re typically made of dense metals or alloys. Shops have to employ sturdy machines with powerful cooling and vibration damping. Because the drive for cleaner energy is relentless, so is the demand for these big, rugged parts.

Precision matters most for energy parts since even the smallest mistakes can result in leaks, loss, or downtime. Heavy workpieces, tight deadlines, and ever-stricter global safety codes all pose key challenges.

Heavy Equipment

Heavy equipment manufacturers use large CNC machining to construct frames, engine blocks, and hydraulic components for construction and mining equipment. These components need to withstand hard abuse and provide years of service with minimal upkeep.

Generally, the machining process forms thick steel or cast iron into finished shapes, sometimes with just millimeter tolerance. Some carve large, intricately shaped gear housings and undercarriage components, slashing cycle times and manpower requirements.

The size and weight of these parts makes manual work hard, so automated CNC setups are a must. New tech allows more parts to be produced with less changeovers, assisting businesses manage larger orders and custom commissions. For global markets, this reliability and flexibility is crucial.

Other Notable Sectors

The automotive sector uses big CNC machining for engine heads, transmission cases, and body frames.

Marine builders require large corrosion-resistant parts for vessels navigating the world’s oceans.

Medical device manufacturers lean on CNC for surgical instruments and imaging equipment components.

Defense and firearms require rugged, extremely precise parts for weapons and vehicles.

Music instrument makers use CNC for detailed, repeatable shaping.

The Economics of Scale

Large CNC machining is at the heart of manufacturing economics today, especially for companies with large parts machining needs. The scope and scale of these operations, including precision machining and high horsepower machining, impact cost, speed, and long-term flexibility, making it crucial for practitioners to understand the potential economies of scale.

Initial Investment

Upfront capital for large parts CNC machining needs can be significant. These machines often require custom installation, reinforced foundations, and specialized power supplies. In addition to the machinery, buyers must consider tooling, safety systems, and digital controls. For example, a horizontal machining center with multi-pallet capability can cost hundreds of thousands of dollars.

Several variables influence these initial expenses. Production volume targets, material complexity, and part geometry all play a role in machine selection. Facilities may need physical enhancements or temperature regulation to meet their large machining needs. Furthermore, employee training represents another upfront cost, especially when adopting new technology.

Small-scale producers encounter a higher entry hurdle because of these needs. ROI is a function of throughput and cycle time and scale with the capacity to amortize fixed costs over big batches. High-volume jobs take the most advantage, since the per-part cost decreases with more parts machined. Firms can minimize payback periods by smart scheduling and decreasing tool changeover.

Financing options for large machining projects include leasing, equipment loans, and government incentives. These alternatives can ease the financial burden and speed up adoption, balancing flexibility and long-term commitment.

Operational Costs

Operating large CNC machines carries recurring costs. Power, coolant and consumable tooling all add up. Operators, maintenance technicians — and wages to match their skill. Bigger machines can additionally require increased floor space, increasing facility costs.

Drivers of high operational costs are complex part geometries, hard-to-machine materials and a high number of tool changes. Maintenance and unexpected downtime can rapidly eat into margins. Cycle time is still an important measure, as quicker fabrication reduces labor and overhead costs per unit.

Firms can save by investing in automation–for example, robotic part loaders. Optimizing tool paths and tool life reduces scrap and waste. Predictive maintenance and remote monitoring prevent expensive breakdowns.

Out situations are expensive. Even a brief machine downtime can wreck production timelines and increase unit costs. Preventive maintenance and regular calibration are key to keeping machines operating at peak efficiency.

Value Proposition

Large CNC machining represents an obvious value for manufacturers requiring high precision and repeatability. These machines can maintain tight tolerances over hundreds or thousands of pieces, enabling industries where quality is non-negotiable.

Accuracy and scale are good selling points. By making more units per run, they reduce their unit cost. Being able to run big batches or changeover from job to job with little setup allows you to respond to shifting market needs. Contemporary CNC systems are flexible enough to handle nearly any material and part design.

Modern manufacturing is all about scale and scale is all about speed. Large machining solutions dominate in cycle time reduction and throughput increase, a lifeblood for industries such as automotive, aerospace and energy.

Multitasking machines — like those with pallet changers — let companies go after complicated jobs with fewer processes, again increasing efficiency. A powerful moat arises from your ability to capitalize on economies of scale. Corporations that own big CNC machining usually own the cost advantage, the quality advantage, and the delivery advantage. This sets them up well in the world economy and draws high-value jobs.

Conclusion

Large CNC machining is at the heart of our era’s heavy industry. Shops employ these to machine steel blocks, contour beams and craft large moulds for aircraft and ships. Each installation requires robust equipment, intelligent software, and intelligent people. Shops rely on immediate data and check every piece against tough standards. This work keeps expenses in check and enables teams to tackle large projects in areas such as power, auto, and health tech. To go further, discuss with others in the trade, exchange what works and inquire about newest tools. Your voice defines this space—participate, discover, and contribute to shaping the next cycle of intelligent machining concepts.

Frequently Asked Questions

What is large CNC machining?

Large CNC machining utilizes computer-controlled machinery to fabricate or sculpt sizable components, meeting the large parts machining needs of industries requiring accurate, high-quality components from metal, plastic, or various materials.

Which industries benefit most from large CNC machining?

Aerospace, automotive, energy, and construction sectors demand superior machining services, as they require large precise parts for machinery, vehicles, and structures.

How does large CNC machining ensure accuracy?

Large CNC machining services utilize high-end software and precise sensors, which track and control the machining process to ensure precision and repeatability in crafting complex industrial components.

What are the main machine architectures used?

The primary architectures, including gantry and bridge mills, are essential for large parts CNC machining needs and accommodate various part sizes and shapes.

Why is digital technology important in large CNC machining?

Digital technology in modern CNC machining enhances accuracy and monitors quality, facilitating real-time tracking to minimize mistakes and downtime during challenging machining tasks.

What quality checks are used in large CNC machining?

Quality checks, including precision machining inspections with coordinate measuring machines and 3D scanning, ensure that each component meets rigorous specifications before shipment.