High- CNC machining Services

for Custom Metal Parts

alloy steel, aluminum, and copper components with unparalleled precision.

Start A New CNC Quote

Start to Upload Your Files

Start to Upload Your FilesSTEP STP SLDPRT IPT PRT SAT IGES IGS CATPART X_T OBJ STL files

ISO

9001:2015 Certified

60+

CNC Machines

100+

Metal materials

1000+

CNC Design Case

CNC Machining Services for Custom Parts

FERR specializes in high-precision CNC machining services for efficient and stable delivery of both complex structures and parts with high tolerance requirements. We are equipped with multi-axis CNC milling machines, lathes, EDM, precision grinding and many other types of equipment, which support the integration of the whole process of milling, turning, drilling, tapping, fine grinding and other processing.

Custom CNC Milling Services

Our 3-axis, 4-axis, and state-of-the-art 5-axis machining centers are capable of accurately handling highly complex geometries and extremely tight tolerances in metal part fabrication.

Custom CNC Turning Services

Equipped with CNC lathes, mill-turn machines and automatic feeding systems, FERR specializes in machining shafts, cylinders and complex shapes. And we can turn prototypes from turning to mass production in just a few days.

Why Choose ferr with CNC Machining

We specialize in CNC Machining, providing high-performance, durable solutions for CNC customer parts. Our precision machining and modular customization ensure quick turnaround and compatibility with industry standards.

ISO certified production

FERR is an ISO9001-2015 certified manufacturer that guarantees the highest quality of parts in an industry that demands strict consistency and quality control.

Fast quote and delivery

Our extensive network of facilities and partners allows us to fulfill orders quickly, regardless of volume or complexity. (minimum 1 day shipment)

Flexible Starting Quantity

We understand that not every project starts with large quantities. That's why we offer flexible starting quantities that allow you to prototype, test and scale to your needs without compromise.

Extensive industry experience

We've been manufacturing CNC customer parts for 16 years, and our skilled engineers know how to get the best results from your design.

Get your CNC prototyping and production

parts made today

All information and uploads are secure and confidential.

One-Stop CNC Machining Parts Supplier

CNC machining is the perfect solution for both low-volume prototypes and high-volume production runs, delivering consistent precision and quality from 1 to 10,000+ parts. At Ferr, we offer a full range of custom CNC machining services tailored to your exact design, material, and tolerance requirements.

Rapid Prototyping

Ferr helps you accelerate product development with precision CNC-machined prototypes delivered in just a few days. Validate your design with real parts — fast.

Low-volume Manufacturing

Whether you're testing the market or preparing for scaled production, Ferr offers cost-effective CNC manufacturing from 10 to 1,000+ pieces — with production-level quality.

End-use Production

From durable industrial components to custom mechanical parts, Ferr’s CNC production ensures stable quality across thousands of units. Perfect for both small and large-scale batch production.

FERR-cNC Machining Process Overview

cNC-Machining Process Flowchart

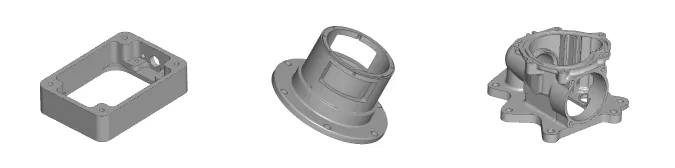

Typical Precision Machined Products

Flange, Bearing Housing

Treatment: pickling

Application: chemical industry

Industrial equipment parts

Treatment: burnish

Application: Industrial equipment

Industrial connectors

Treatment: burnish

Application: Industrial equipment

Pump and compressor parts

Treatment: Polished, anodized

Application: Liquid Transfer Systems

Turbocharger parts

Treatment: Polished, anodized

Application: Automotive

crankshaft support

Treatment: Polished, anodized

Application: Automotive

super gears

Treatment: sandblast

Application: Industrial equipment

Concrete Pump

Treatment: Plating, Powder Coating

Application: Construction equipment

Fuselage frame

Treatment: Polished, anodized

Application: automobile industry

Oil pump housing

Treatment: aluminum

Application: Automotive

Motor base

Treatment: Brushed/polished

Application: Machinery

transmission (i.e. gears)

Treatment: Plating, Powder Coating

Application: Machinery Manufacturing

Common Materials

stainless steels

| austenitic stainless steel |

|---|

| 304: good corrosion resistance |

| 316: higher corrosion resistance |

| 321: with Ti |

| 310s: Excellent high temperature performance |

| ferritic stainless steel |

|---|

| 430:Commonly used ferrite models |

| 409: heat-resistant |

| 439: Weldability better than 430 |

| 200 Series |

| martensitic stainless steel |

|---|

| 410: good mechanical properties |

| 420: High hardness, cutting grade |

| 440C: Excellent hardness and wear resistance |

| 100 Series |

| Precipitation hardening stainless steel |

|---|

| 17-4PH: High mechanical strength and good corrosion resistance |

| 15-5PH: Better toughness |

| 500 Series |

| Duplex stainless steel |

|---|

| 2205: High corrosion resistance |

| 2507: Super duplex stainless steel for harsh environments |

| 400 Series |

alloy steel

| Low Alloy Steel |

|---|

| 16Mn:High manganese content |

| Q345:Small amount of MnSi |

| 20CrMnTi:Contains chromium, manganese and titanium, high hardness |

| AISI 4130:Contains chromium-molybdenum, good toughness |

| AISI 4140:Excellent heat treatment performance |

| Copper Alloys |

|---|

| H62:62% copper for good plasticity and corrosion resistance |

| H68:68% copper for high conductivity |

| ZCuSn10:Contains about 10% tin, good corrosion and wear resistance. |

| ZCuAl9Mn2:Aluminum bronze for wear and impact resistance |

| B10:10% nickel for seawater corrosion resistance |

| B30:30% nickel for higher temperature resistance |

| Aluminum Alloys |

|---|

| 6061:Contains magnesium and silicon for high strength and corrosion resistance |

| 7075:Contains zinc-magnesium-copper for extreme strength |

| A356:High silicon content, good casting performance |

| ZL101:High heat resistance, low density |

| Superalloys |

|---|

| Inconel 718:Containing nickel-chromium, high temperature resistance, strong oxidation resistance |

| Hastelloy C-276:Contains nickel, molybdenum and chromium for excellent corrosion resistance |

| Haynes 25:Containing cobalt-nickel-chromium, with high resistance to oxidation and creep. |

| Stellite 6:Contains cobalt-chromium tungsten, resistant to wear and corrosion |

| A-286:Containing iron-nickel-chromium-molybdenum-titanium, good overall performance |

| Alloy 800:Containing FeNiCr, high temperature and corrosion resistant |

carbon steel

| mild steel |

|---|

| Q195:Good plasticity and workability |

| Q235:Moderate strength, excellent toughness |

| A36:Good weldability, good low temperature performance |

| medium carbon steel |

|---|

| 45#:High hardness and good wear resistance after tempering |

| 40Mn:High strength and excellent toughness |

| AISI 1045:Excellent overall performance after tempering |

| high carbon steel |

|---|

| T8:High hardness, good wear resistance |

| T10:suitable for cold work molds |

| AISI 1095:Very high hardness and wear resistance |

I don't have complete drawings, can I send inquiry?

Yes, we can help you analyze based on your description, samples and photos.

I am not sure if you can do my parts?

Most of our customers come to us because “others say they can’t do it”.

Are you a factory or a trader?

We are a factory and have a project management team that can handle the technology, cost and delivery at the same time.