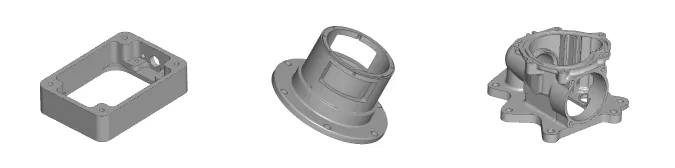

One-Stop Aluminum Die Casting Parts Manufacturer

Proven Aluminum Die Casting Parts

Start A New Quote

Start to Upload Your Files

Start to Upload Your FilesSTEP STP SLDPRT IPT PRT SAT IGES IGS CATPART X_T OBJ STL files

What is aluminium die casting?

Aluminium die casting has become one of the most reliable solutions for lightweight, high-strength metal parts, especially in automotive, electrical, and machinery industries. Yet behind every flawless casting lies a process far more intricate than it appears.

Many factories can produce aluminium castings, but only experienced teams understand the real challenges — metal flow control, gas porosity, shrinkage, and surface flatness. Each of these directly affects dimensional accuracy and mechanical strength. Through thousands of production trials,

FERR has developed a strict mould design protocol and advanced vacuum die casting technology to minimize defects and stabilize internal density.

Material selection also plays a decisive role. We conduct alloy analysis to match mechanical properties with specific applications — from ADC12 for general structural parts to A380 and A356 for high-precision housings. Our temperature and pressure control systems are fully automated, ensuring consistency from shot to shot.

Focus on Aluminum Die Casting Parts Parts

Our Aluminum Die Casting Parts Parts Are Engineered to Meet the Demanding Requirements of Applications Worldwide. to discuss your project requirements. Get in touch to discuss your project

High-Quality Aluminum Alloy Gravity Cast Hardware Shell Parts

Aluminium Metal Cast Pump and Valve Components

Aluminum Gravity Casting for Automotive

Precision Die Casting Aluminum Hook for Washing-Machine

Precise Casting Services Vehicle Parts

Customized Casting Solution Processing Aluminum Alloy Home Washing Machine Components

Custom Aluminum Die Casting Parts for Motorcycle

Complex Geometric Aluminum Die Castings

Electronic Box Casing Custom Aluminum Die Casting

Auto Engine Body Part Aluminum Die

Aluminium Motor Housing Casting

Aluminum Alloy Die-Cast Automotive Parts

Aluminum Alloy Die Casting Heatsink for Electronics

I don't have complete drawings, can I send inquiry?

Yes, we can help you analyze based on your description, samples and photos.

I am not sure if you can do my parts?

Most of our customers come to us because “others say they can’t do it”.

Are you a factory or a trader?

We are a factory and have a project management team that can handle the technology, cost and delivery at the same time.

Advantages Of Our Aluminum Die Casting Parts

Aluminum die casting enables manufacturers to produce high-precision parts with excellent dimensional stability, strong mechanical properties, and consistent quality across every batch. For applications that require strength-to-weight performance, complex geometries, and reliable mass production, this method delivers clear advantages.

Our Aluminum Die Casting Manufacturing Approach

Our die-casting workflow focuses on dimensional stability, repeatability, and efficient mass production. By controlling each stage—from mold design to casting, trimming, machining, and inspection—we ensure every aluminum component meets required tolerances and long-term performance.

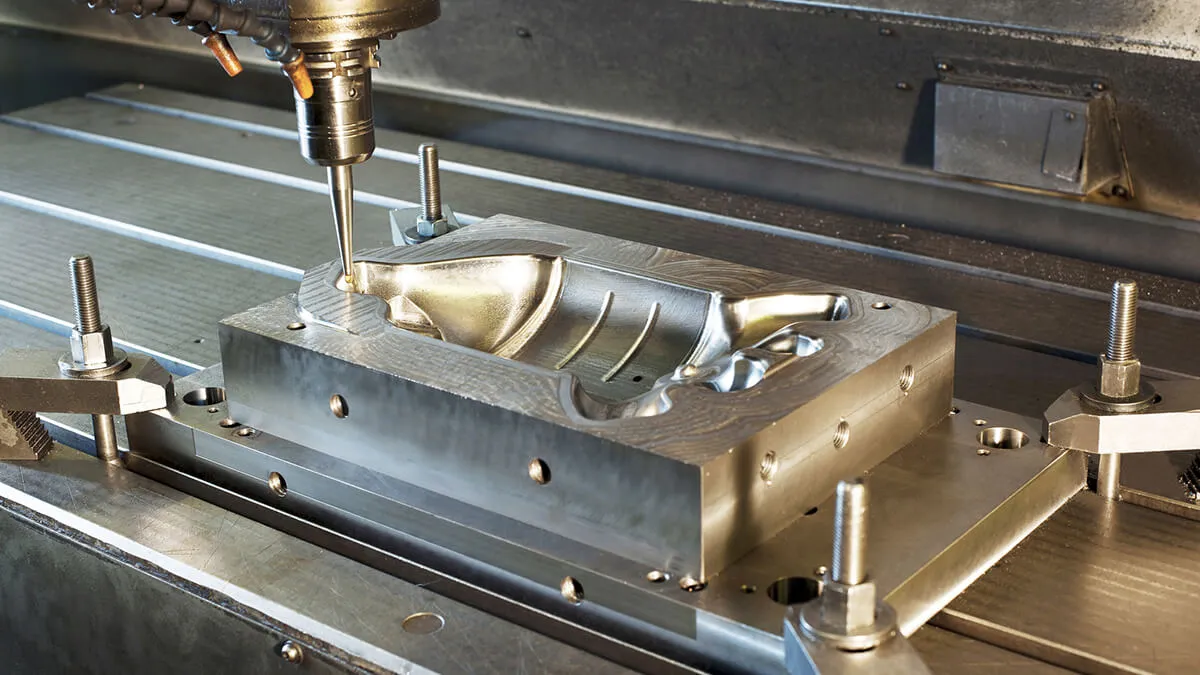

Mold Design & Material Preparation

Our engineers design high-precision steel molds based on your geometry, wall thickness, draft angles, and mechanical requirements.Before casting, aluminum ingots (ADC12, A380, A383, etc.) are melted and refined to remove impurities and ensure stable fluidity.

High-Pressure Die Casting (HPDC) Process

Molten aluminum is injected into the mold cavity under fast fill speed and high pressure (up to 1500 bar). Process parameters—temperature, injection speed, pressure curve, cooling layout—are tightly controlled to ensure consistent density and surface quality.

Trimming, Deburring & Secondary Machining

After casting, gates and flash are trimmed with hydraulic presses. Critical surfaces, threads, holes, and tolerance-sensitive areas undergo CNC machining to achieve the required precision.

Quality Inspection & Performance Verification

Every casting passes through multiple checkpoints: X-ray for internal porosity (when required), Dimensional inspection (CMM, gauges, pin checks), Surface porosity & blistering check, Mechanical strength & coating adhesion test (for coated parts)

Aluminum Die Casting Equipment & Capabilities

Our die casting workshop is equipped with cold chamber and hot chamber die casting machines ranging from 88T to 2000T, covering diverse tonnage requirements from miniature electronic structural components to large automotive parts.

| Equipment | Mold Size(mm) | Process | Suitable Materials | Typical Applications |

|---|---|---|---|---|

| 88T Hot Chamber Machine | 200 × 100 | Hot Chamber | Aluminum Alloy / Zinc Alloy | Microstructural components, hardware fittings, and small appliance assemblies |

| 180T Cold Chamber Machine | 180 × 80 | Cold Chamber | Aluminum Alloy / Zinc Alloy | Consumer electronics enclosures, lightweight hardware, instrument components |

| 280T Cold Chamber Machine ×2 | 280 × 180 | Cold Chamber | Aluminum Alloy / Zinc Alloy | Precision housings, small mechanical components, and accessories for daily necessities |

| 350T Cold Chamber Machine | 280 × 180 | Cold Chamber | Aluminum Alloy / Zinc Alloy | Medium-sized housing assemblies, small-batch custom parts |

| Equipment | Mold Size(mm) | Process | Suitable Materials | Typical Applications |

|---|---|---|---|---|

| 420T Cold Chamber Machine | 350 × 250 | Cold Chamber | Aluminum Alloy / Zinc Alloy | Medium-sized engineering components, durable housings |

| 560T Cold Chamber Machine | 350 × 250 | Cold Chamber | Aluminum Alloy / Zinc Alloy | Automotive components, appliance housings, industrial structural parts |

| 800T Cold Chamber Machine | 600 × 500 | Cold Chamber | Aluminum Alloy / Zinc Alloy | Medium to large industrial components and structural support elements |

| Equipment | Mold Size(mm) | Process | Suitable Materials | Typical Applications |

|---|---|---|---|---|

| 1000T Cold Chamber Machine | 600 × 500 | Cold Chamber | Aluminum Alloy / Zinc Alloy | Large-sized industrial enclosures, load-bearing structural components |

| 1250T Cold Chamber Machine | 700 × 550 | Cold Chamber | Aluminum Alloy / Zinc Alloy | Automotive structural components, aerospace parts, mechanical framework components |

| 2000T Cold Chamber Machine | 1000 × 660 | Cold Chamber | Aluminum Alloy / Zinc Alloy | Extra-large monolithic structural components, high-strength mechanical parts |

Our Aluminum Die Casting Services

Choosing the right casting method is critical for strength, dimensional stability, surface quality, and long-term performance. Our aluminum die casting solutions combine modern cold-chamber equipment, automated feeding systems, and strict quality control to deliver reliable, production-ready components for global industries.

Aluminum Die Casting

Best suited for medium- to high-volume production of lightweight, complex parts requiring tight dimensional accuracy. Ideal for automotive housings, consumer electronics frames, power-tool bodies, appliance components, and structural brackets. Provides excellent strength-to-weight ratio, stable dimensions, and high production efficiency.

Capability

Description

Material Options

A380, ADC12, A360, A413, A356, Zinc Alloy (if needed)

Minimum Wall Thickness

Down to 1.0–1.5 mm depending on part geometry and alloy

Maximum Casting Size

Up to 700×550 mm for large cold-chamber machines (Supporting 88T–2000T equipment)

Weight Range

From 30 g small housings to 8–10 kg structural castings

Surface Finish

Raw as-cast, shot-blasting, tumbling, polishing, machining, powder coating, anodizing (select alloys)

Manufacturing Features

Integrated ribs • Insert casting (steel parts / brass threads) • Thin-wall sections • High-complexity geometry • Automated trimming & deburring

Post-Machining & Surface Processing

To achieve critical tolerances and functional surfaces, pressure die-cast parts often require secondary operations. We provide full in-house machining, drilling, tapping, grinding, and finishing to bring each casting to its final specification.

Capability

Description

Machining Operations

CNC milling, drilling, tapping, reaming, surface machining, flatness correction

Tolerance (After Machining)

±0.005–0.01 mm depending on geometry and machining depth

Porosity Control

Vacuum die casting (optional), real-time process monitoring, optimized gate & overflow design

Inspection Capabilities

CMM, digital calipers, X-ray inspection (optional), pressure leak testing, tensile & hardness testing

Surface Treatments

Powder coating, wet painting, anodizing (depending on alloy), electrophoresis, chromate conversion

Production Support

Tooling optimization, mold flow analysis, draft angle evaluation, rib & boss design guidance

Inside FERR’s Aluminium Die Casting Workshop

Every die casting begins here — in a fully integrated aluminium foundry where melting, injection, trimming, machining, and surface finishing are completed under one roof. From mold design to final inspection, each process is precisely managed to ensure stable quality, dimensional accuracy, and flawless surface performance.

Melting And Die-Casting Workshop

Die-casting machine

CNC Workshop

Auto Cleaning Line

Negative Pressure Casting

Casting Production Line

How to Work With us

Provide 3d drawings

Evaluate the quotation

Manufacturing

Order delivery

Get 3-day standard lead times on simple parts between 10 mm x 10 mm and 200 mm x 200 mm. Upload your part to see if it’s eligible.

Frequently asked questions

Drawing evaluation: 1-2 business days

Prototype production: 5-10 business days

Small-batch production: 10-15 business days

Large-scale production: 15-30 business days

Rush service: 72-hour rush service available (additional fees apply)

We have established a comprehensive quality management system:

ISO 9001:2015 Certification: International quality management standard

First Article Inspection: 100% confirmation of the first piece before mass production

Process Control: 100% inspection of critical processes

Finished Product Inspection: Full dimensional inspection using CMM coordinate measuring

Quality Traceability: Complete production and inspection records

We support both small-batch prototyping and large-scale production. MOQ starts from as low as a few dozen pieces, and high-volume orders up to hundreds of thousands are welcome.

Yes. Besides producing according to drawings, we provide DFM (Design for Manufacturability) support to reduce costs and improve efficiency.

Pricing is based on material, process complexity, order volume, and delivery requirements. We aim to offer the most cost-effective solution for every project.

We serve automotive, machinery, electronics, medical devices, and energy sectors. From precision parts to structural components, we have extensive expertise.

Ready to Start Your Custom Manufacturing Project?

Whether you have detailed drawings or just a concept, we’re ready to listen.