Precast Concrete Accessories

specialized manufacturer

ISO

9001:2015 Certified

Professional Quality Management System

60+

Production Machines

Covering stamping, welding, CNC, anchoring processes

100+

Steel Grades

Carbon steel, stainless steel, alloy steel...to meet the needs of different working conditions

800+

Custom Projects Delivered

Serving large-scale projects such as subways, high-speed railways and assembled buildings

Why manufacture Precast Concrete Accessories with FERR?

We specialize in custom precast concrete accessories, delivering high-performance, durable solutions for construction, infrastructure, and civil engineering projects. Our precision machining and modular customization ensure quick turnaround and full compatibility with industry standards.

ISO certified production

FERR is an ISO9001-2015 certified manufacturer that guarantees the highest quality of parts in an industry that demands strict consistency and quality control.

Fast quote and delivery

Our extensive network of facilities and partners allows us to fulfill orders quickly, regardless of volume or complexity. (minimum 1 day shipment)

Flexible Starting Quantity

We understand that not every project starts with large quantities. That's why we offer flexible starting quantities that allow you to prototype, test and scale to your needs without compromise.

Extensive industry experience

We've been manufacturing Precast Concrete Accessories for 16 years, and our skilled engineers know how to get the best results from your design.

One-stopPrecast Concrete AccessoriesSolution Service

We help customers streamline their workflows and reduce on-site assembly time through fast sampling, rigorous load testing, and a wide selection of durable, application-specific materials and finishes.

*To learn more about how we can help with your Precast Concrete Accessories, contact us today for a free quote.

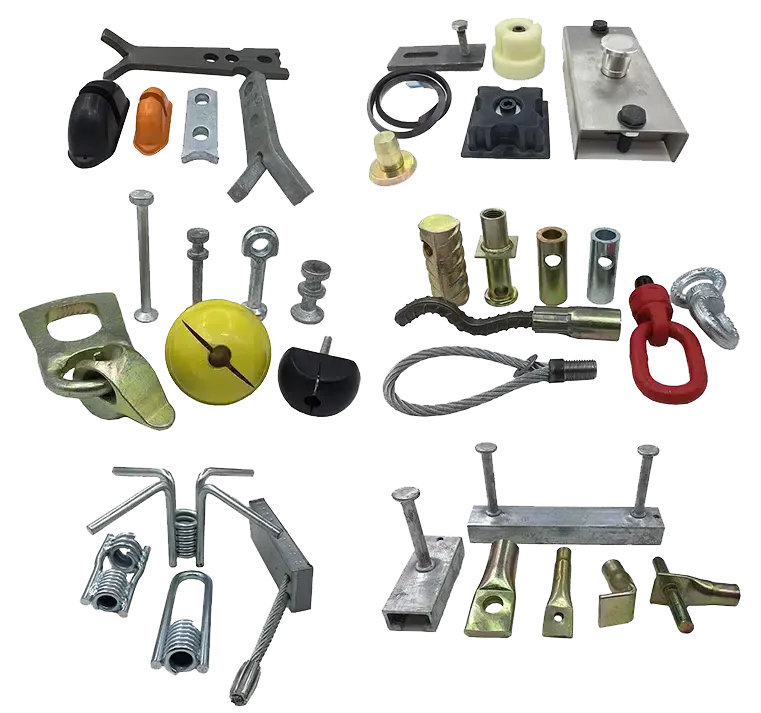

At Ferr, we provide rapid prototyping and full-range manufacturing services for Precast Concrete Accessories used in industrial, civil, and infrastructure projects. From lifting anchors and magnetic formwork systems to spacers, fixing bolts, and positioning tools, our complete product lineup supports one-stop sourcing for all your precast construction needs.

What kind of Precast Concrete Accessories can we make?

Lifting Systems

We supply a wide range of Lifting Systems for Precast Concrete Unit, ensuring safe and efficient handling from production to installation.

Fixing & Fastening

Our Fixing System For Precast Concrete Unit—including threaded inserts, anchor channels, and bolt sleeves—supports building components' reliable attachment to precast elements.

Connection System

Our Connection System For Precast Concrete Unit joining system is dedicated to the lifting, positioning, fixing and demoulding of the elements at every stage of the process.

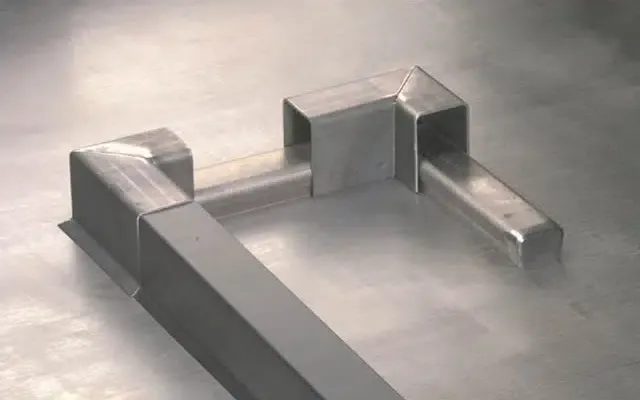

Magnetic Formwork Systems

We offer modular magnetic formwork solutions that streamline mold setup for slabs, walls, and custom precast shapes.

Every Detail Tested. Every Part Trusted.

Whether it's a high-voltage line or a complex customized component, our rigorous testing ensures long-term reliability in the field.

Re-inspection before leaving the factory

After completing the initial inspection and assembly process, we will carry out a second quality inspection on each batch of embedded parts, focusing on reviewing the key dimensions, welded parts, surface rust treatment and marking integrity. Through a combination of manual sampling and instrumental measurements, we ensure that each finished product meets the standards of structural consistency and traceability before leaving the factory.

Tensile Load Test for Fixing Components

To ensure the reliable bearing capacity of the embedded parts in the concrete structure, we carry out rigorous mechanical property tests on the finished products, including pull-out and shear strength tests, to verify the stability of the anchors under axial and transverse forces, respectively; at the same time, all the loading processes simulate the actual construction conditions as much as possible, such as lifting and removal of formwork, and other stress conditions.

Material Verification Before Production

All raw materials are verified before processing. Our lab performs chemical composition analysis using spectrometers to confirm the material grade and compliance with industry standards. For key parts, we also test mechanical properties like tensile strength and hardness to ensure they meet project requirements. This ensures every batch of fittings starts with the right foundation.

CMM Inspection for Dimensional Accuracy

We use (CMM) to inspect critical dimensions of precision parts. With sub-micron accuracy, the CMM checks whether each component matches the 3D drawing — especially for tight-tolerance areas like holes, threads, and interfaces. This process helps guarantee consistency and compatibility during final assembly.

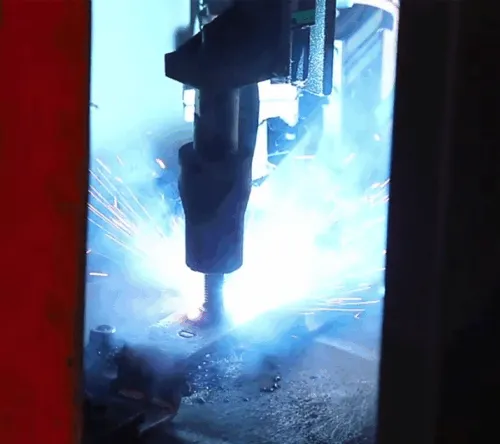

High standard rapid - manufacturing

FERR's 56 skilled technicians, semi-automated production lines and strict process controls ensure that your fittings are not only strong, but also repeatable, accurate and ready to install.

At FERR, rapid manufacturing doesn't mean cutting corners. It means that every process, from drawing review and prototyping to full-scale production, is tightly controlled to deliver high-quality customized Precast Concrete Accessories. Supported by experienced engineers and in-house equipment, we can quickly and reliably turn complex requirements into finished components.

Building Embedded Parts

We offer OEM/ODM services based on your requirements, drawings, and specific parameters. With industry-leading precision and minimal tolerances, our embedded parts are guaranteed to meet your exact expectations.

The products shown here are examples of parts we’ve made for previous clients, and they are for reference only. Since every project has unique specifications, we do not list fixed parameters. Feel free to upload your drawings or contact us for a custom quote.

Lifting Sockets Concrete Tubular

Treatment: Stamping,Bending,Welding, etc

Lifting Sockets With Bended

Treatment: Stamping,Bending,Welding, etc

M12/16/20/24 BSR External socket

Treatment: Stamping,Bending,Welding, etc

Ring Clutch For Flat Lifting System

Treatment: Stamping,Bending,Welding, etc

Spherical Head Anchor Lifting

Treatment: Stamping,Bending,Welding, etc

Lifting Ring Clutch for Erection Anchor

Treatment: Stamping,Bending,Welding, etc

Lifting Loop Precast Concrete

Treatment: Stamping,Bending,Welding, etc

Welded plate lifting anchors

Treatment: Stamping,Bending,Welding, etc

Heavy Duty Lifting Anchors

Treatment: Stamping,Bending,Welding, etc

Crowned foot anchor with socket

Treatment: Stamping,Bending,Welding, etc

Carbon steel forged eyebolts

Treatment: Stamping,Bending,Welding, etc

Corrugated Rebar Crown Leg Anchors

Treatment: Stamping,Bending,Welding, etc

Fixed Anchor Connection Anchor

Treatment: Stamping,Bending,Welding, etc

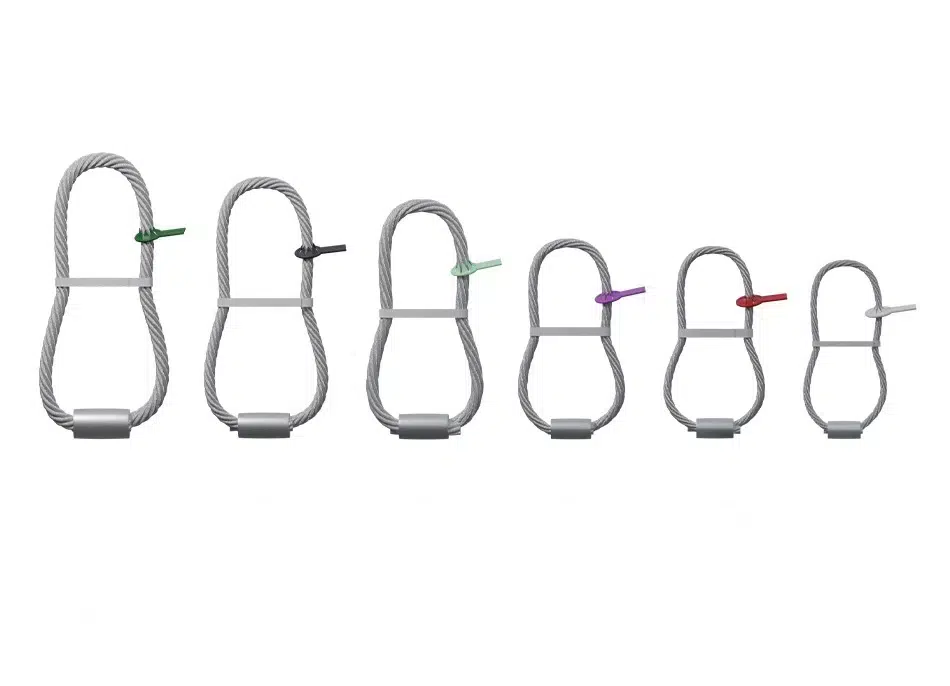

Steel Cable Wire Rope Sling

Treatment: Stamping,Bending,Welding, etc

Flange Head Galvanized Concrete Bolts

Treatment: Stamping,Bending,Welding, etc

Materials & surface finishes for Precast Concrete Accessories

With our flexible manufacturing network, you have the flexibility to choose from hundreds of industrial materials and a wide range of surface treatments to meet a variety of structural, functional and cosmetic needs.

Precast Concrete Accessories Materials

Carbon and alloy steels

Q235, Q345, SPCC, 1018, 1020, 4140 – ideal for structural strength and mounting brackets

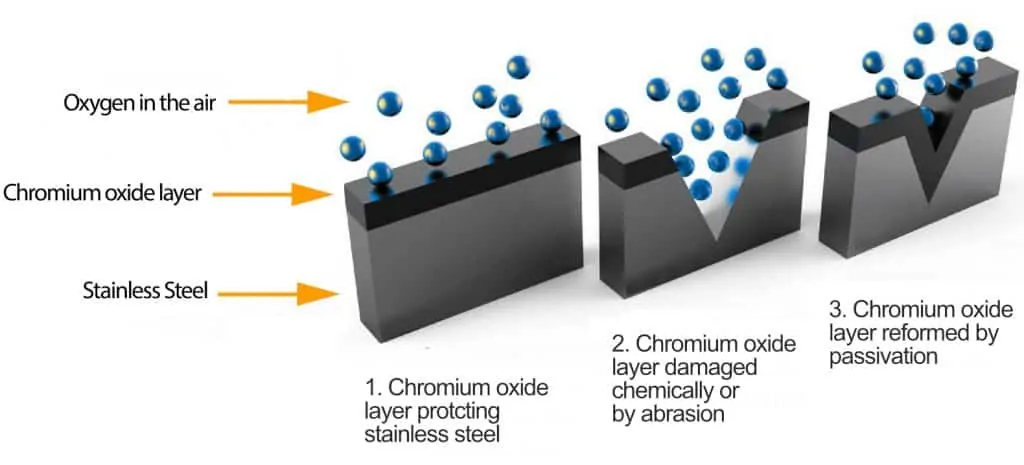

Stainless Steel

304/304L, 316L, 430 – corrosion resistant for indoor and data center environments

Aluminum

5052, 6061-T6, 6063 – lightweight and corrosion resistant for doors, panels and rails

Surface Finishes

Powder coating, anodizing, brushed finish, electropolishing, zinc plating — To meet electrical, aesthetic, or durability requirements

Precast Concrete Accessories Surface Finishes

Powder Coating

Used for visual identification or protection of accessories like panel connectors and brackets

Black Oxide Coating

Low-gloss finish to reduce glare and increase corrosion resistance on exposed parts

Hot-Dip Galvanizing

Most common anti-corrosion finish for steel embeds and lifting anchors

Electropolishing

Smooth, clean finish for stainless steel parts, improving corrosion resistance

Passivation (for stainless steel)

Improves corrosion resistance by removing surface iron and enhancing chromium layer

How to Work With us

Provide 3d drawings

Evaluate the quotation

Manufacturing

Order delivery

Get 3-day standard lead times on simple parts between 10 mm x 10 mm and 200 mm x 200 mm. Upload your part to see if it’s eligible.

Can you manufacture based on customer drawings?

Absolutely. We work directly with customers’ 2D/3D CAD files and offer full custom manufacturing based on your technical drawings and specifications.

What’s your typical lead time?

Lead time depends on part complexity and order volume. For most prototypes or low-volume runs, we offer lead times as fast as 5–7 working days. Rush orders can often be accommodated.

Are your lifting anchors certified to meet national load standards (EN, ASTM, GB)?

Yes. Our lifting systems are tested and certified to comply with EN 1992-4, ASTM A1064, or GB/T standards, depending on customer needs.

Can you provide technical datasheets and installation guidelines?

Yes. We offer complete datasheets, 3D models, and installation instructions to help your team use our products correctly and safely.

What’s the pull-out strength or load rating of your fixing inserts?

Pull-out strength varies by type, thread size, and embedment depth. All products are tested and rated per international standards.

Do you offer customized accessories for special precast shapes or thin sections?

Yes. We support tailored solutions for complex or thin-wall precast elements. Our engineering team will assist with design optimization.