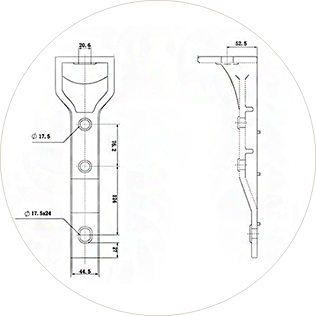

Guard Arm Brace

Main Product Features

- Compatible with standard guard arms and crossarms

- Multiple brace styles: single, double, and angle

- Heavy-gauge steel construction with HDG finish

- Reduces conductor sag and vibration under load

- Fully customizable to match pole geometry

OEM/ODM Service

FERR assists you throughout the project: selection of materials suitable for the electrical environment, optimization of mechanical load-bearing structures, corrosion-resistant surface treatments, analysis of interface compatibility, improvement of insulation properties, as well as customized installation dimensions and hardware accessories. We continue to provide you with solutions and assistance.

Large or Small Order

Whether you have a long term project that requires bulk deliveries or a small order with just a few samples, FERR will support you with the same professionalism and responsiveness.

Our flexible production model enables the rapid sampling of multiple categories and small quantities, as well as the stable production of large-scale customized parts. From engineering evaluation and process selection to sampling, quality control, and shipping, our team works efficiently together to ensure consistent and reliable delivery, regardless of the order size.

*Provide your application requirements—such as stress conditions, materials, size range, and even product name. We are always available for customization, so please contact us directly.

Product introduction

A protective arm bracket is a special bracket for electrical cross-arms, usually bolted and fastened with screws, that effectively supports the cross-arm and ensures its stability in power and telecom buildings.

FERR’s Guard Arm Brace is designed to support protective arms that are located underneath the primary conductor and carry neutral or communication wires. The primary purpose of these brackets is to improve the safe spacing of multi-wire poles and increase overall safety.

Technical Manufacturing Standards

| MOQ | ≥1 Piece |

| Manufacturing Methods | OEM /ODM(According to Drawings) |

| Size (section) | 40x40mm ~ 100x100mm (square tube/angle/channel etc.) |

| Length range | 400mm ~ 6100mm |

| Material | Q235, Q345, SS304, SS316 |

| Thickness | 3mm ~ 10mm |

| Load Rating | 2kN ~ 200kN (designed according to customer’s drawing/use requirements) |

| Surface treatment | hot dip galvanized (ASTM A123/ISO1461), cold galvanized, sprayed, Dacromet |

| Processing | Stamping, welding, hole cutting, grooving, end capping, etc. |

| Application features | single/double side hole arrangement, high corrosion resistance requirements, adapted to high-voltage power transmission scenarios. |

| QA Service | Yes |

| Installation Guidance | Yes |

| Freight Solutions | Yes |

| After Services | Yes |

Why choose FERR's

Guard Arm Brace

At FERR, we not only supply industry-standard components but also provide tailored solutions to meet your project requirements. Leveraging our proprietary raw material supply and efficient manufacturing system, we help clients reduce potential risks and hidden costs while ensuring quality and timely delivery.

Every product embodies our OEM/ODM expertise, from material selection to structural design, guaranteeing long-lasting durability.

No Drawings? No Problem.

*With 25 years of experience, we help manufacturers worldwide turn “standard problems” into custom solutions.

sketch design stage

You only need to provide a sample or basic dimensions — our engineers will handle the rest. We turn your ideas into precise technical drawings based on a deep understanding of your actual needs, ensurinYou don’t need to prepare a full 3D model or detailed drawing.

3D modeling and production stage

We build high-precision 3D models based on the initial design, verifying every detail with professional software to meet production standards. Once approved, we move straight into precision manufacturing.

Testimonials

FERR always puts the interests of its customers first.

Yunex

Distribution network project contractors in Southeast Asia

I was most afraid of the drawings sent over to the docking is not clear, the results of FERR engineers directly with me to dock the technical details, and even the bolt hole spacing are confirmed to be very fine. Proofing out once through, no rework, too much trouble.

Orlando J.

Equipment distributors in Europe

Our customers are very picky, especially about the thickness and appearance of the hot-dip galvanized layer, and the goods sent by FERR not only meet the standard, but also the key is that each batch is very stable, and we have never had any problems with the secondary inspection.

Lambrinie

Procurement Manager, X Power Engineering, USA

We started out with just a couple samples to try, and they turned out to be so much better than what we were using before. The dimensional accuracy, surface finish are all spot on and the delivery was fast. Now every time I have a project I go to FERR first, with confidence.

Marco Martinez

Project Manager in the Middle East

I've used quite a few suppliers, some quotes are cheap but with lots of problems.FERR is not the cheapest but they are really the most hassle free. Design coordination, delivery time, packaging details can think ahead of me, I save a lot of energy.

Do you accept small orders?

Absolutely. Our minimum order quantity is 1 piece. You can order a small amount to feel the high quality of our products!

How long is your product warranty?

We offer a 2 years warranty on all our products

What’s your typical lead time?

Lead time depends on part complexity and order volume. For most prototypes or low-volume runs, we offer lead times as fast as 5–7 working days. Rush orders can often be accommodated.

Can I request a sample?

Yes. For Electric Power Fitting, we can provide first article samples upon request. Whether it’s sheet metal, CNC-machined, or assembled parts, we offer sample production to help you evaluate form, fit, and function before moving into full production.

What if the size does not match at the installation site?

We support customized service, in case of size inconsistency, you can contact your account manager at the first time. We will assist in confirming the cause of the problem and provide solutions such as modifying drawings, re-processing or replacing parts to ensure smooth installation of the product and reduce your time and cost loss.

How do you solve the problem of high mold cost and long delivery time?

We provide a variety of low-cost, fast delivery solutions, fusion molding, sand casting, disappearing mold, aluminum mold fast mold, mold sharing mechanism, as well as long-term cooperation mechanism with mold factories, to ensure that the opening of the mold is fast, save money, and do not affect the quality. For trial orders and small batch orders, we also offer flexible development programs to minimize the risk of upfront investment for our customers.

Do you provide type test reports or third-party certifications (e.g., IEC, ANSI)?

Yes. We can provide type test reports and third-party certifications upon request, especially for projects requiring compliance with IEC, IEEE, or national grid standards.