steel cross arm manufacturer

Conforms to ISO 1461 for galvanization

Steel Cross Arm

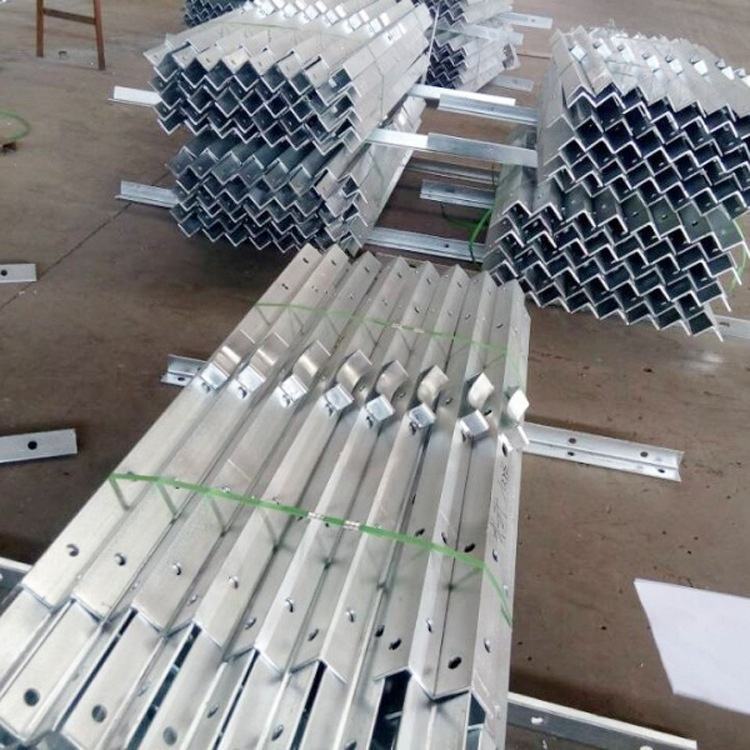

FERR provides a comprehensive line of steel cross arms, engineered to meet the demands of modern power distribution systems. These structural components are widely used in overhead line construction, offering stable support for conductors, insulators, and hardware on utility poles. Built to handle dynamic loads and environmental stresses, FERR steel cross arms are manufactured with high-grade steel and tailored surface treatments for maximum durability.

Each cross arm is precision-formed to ensure consistent dimensions, secure mounting, and ease of integration with pole hardware. Optional bracing, pre-drilled holes, and customizable lengths make them suitable for diverse utility configurations.

To meet utility marking standards and ensure traceability, FERR offers permanent laser or stamp markings on each unit, guaranteeing long-term identification for inspections, upgrades, or replacements.

Steel Cross Arm

For Strength, Stability, And Long-Term Pole Integrity

Steel cross arms chanel are structural essentials in overhead power and telecom line systems, responsible for holding conductors, insulators, and hardware in precise alignment. They support both mechanical loads and electrical system safety, forming a stable backbone for long-span pole networks.

FERR steel cross arms are designed to withstand wind, vibration, and long-term stress while maintaining dimensional accuracy and load integrity—ideal for both urban transmission networks and rural grid extensions.

Ferr delivers steel cross arms with unwavering commitment to performance and consistency:

Steel Cross Arm

Fully customized solutions

FERR provides one-stop services such as technical consulting, pre-shipment inspection, logistics planning, after-sales support, etc. to help customers minimize procurement risks and ensure smooth project delivery.

Full-Size Customization Capability

Ferr customizes tension clamps, suspension clamps, brackets, connectors, and insulator fittings based on drawings or samples, covering various voltages and applications from transmission lines to utility poles.

Multiple Material Options + Strict QS-tandards

Made from forged steel, ductile iron, aluminum alloy, or galvanized steel, all fittings meet IEC/ANSI standards and undergo strict testing to ensure long-term reliability in harsh conditions.

End-To-End Manufacturing Capability, Fast Delivery

From forging to packaging, every step is done in-house. Our experienced team handles OEM/ODM drawings and rapid prototyping to ensure fast response, stable quality, and timely delivery.

Every Detail Tested. Every Part Trusted.

Whether it's a high-voltage line or a complex customized component, our rigorous testing ensures long-term reliability in the field.

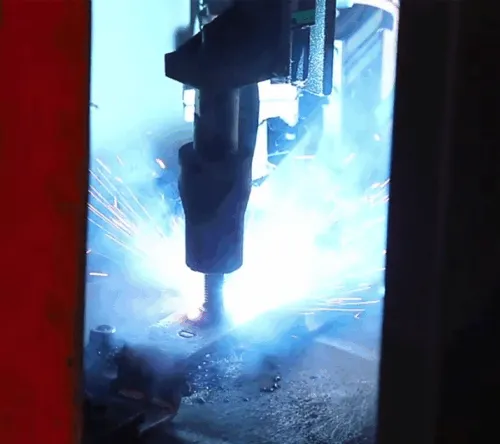

Galvanized thickness testing according to ISO 1461:

The test device is calibrated every 500 tests. It is essential to calibrate the device before each test. According to ISO 1461, articles should have a coating thickness greater than 6 mm and an average coating thickness greater than 85 microns. The surface should be smooth and shiny. If there are sharp edges, workers should use tools to remove them.

Load Test Before Sending Order

There are different types of loading test machines, like straight-up type and laying type. The straight-up type is mainly to test short pole line hardware, like ball sockets, glass insulators, and spindles. The laying type is with more functions. It can test both long and short. The preformed suspension clamp and preformed tension clamp are tested by the laying type.

Material Verification Before Production

All raw materials are verified before processing. Our lab performs chemical composition analysis using spectrometers to confirm the material grade and compliance with industry standards. For key parts, we also test mechanical properties like tensile strength and hardness to ensure they meet project requirements. This ensures every batch of fittings starts with the right foundation.

CMM Inspection for Dimensional Accuracy

We use (CMM) to inspect critical dimensions of precision parts. With sub-micron accuracy, the CMM checks whether each component matches the 3D drawing — especially for tight-tolerance areas like holes, threads, and interfaces. This process helps guarantee consistency and compatibility during final assembly.

Can't find the ideal Steel Cross Arm manufacturer for your industry?

Customized Steel Cross Arm is our strength, we offer customized solutions to all our customers and provide you with the most satisfactory products.

High standard rapid - manufacturing

FERR's 56 skilled technicians, semi-automated production lines and strict process controls ensure that your fittings are not only strong, but also repeatable, accurate and ready to install.

At FERR, rapid manufacturing doesn't mean cutting corners. It means that every process, from drawing review and prototyping to full-scale production, is tightly controlled to deliver high-quality customized electrical fixtures. Supported by experienced engineers and in-house equipment, we can quickly and reliably turn complex requirements into finished components.

Selection guide

FERR will provide you with a selection guide for your needs and will save you money in terms of material and production.

Basic Parameters Determination

According to the voltage level, conductor specifications, tower type and line span, determine the load-bearing grade and electrical performance requirements of the gold fixture. Define the key technical indexes such as mechanical working load, short-circuit current withstand capacity.

Evaluation of environmental conditions

Consider the climate type, filth level, wind speed and ice-covering conditions of the installation location, and select the corresponding anti-corrosion grade. Select salt spray resistant products for coastal areas and focus on UV protection for high altitude areas.

Functional requirements matching

Select corresponding fixtures according to the application function: support rod and street light arm for support function; pole clamp and pin rod for fixing function; wire pulling clip and anchor rod for wire pulling function; and various kinds of fixtures for connecting function.

Standards

Strictly by IEC, IEEE, GB, DL/T and other relevant standards, to ensure that the product complies with ASTM A153 galvanizing standards and ASTM A575/A576 material standards, to ensure compatibility with system components.

Installation & Maintenance

Likewise, FERR provides full installation and maintenance instructions, and our experienced engineers will assist you with their expertise throughout the process.Contact our engineers

Installation

Material Inspection

Confirm that the required number, specification and type of fixtures are complete;

Check whether the surface treatment is complete (e.g. whether the hot-dip galvanized layer is even);

All fittings (nuts, washers, pins, etc.) must be intact.

Tool Preparation

Wrenches, lifting tools, hydraulic shears, punching machines, and other installation equipment;

Personal safety gear (helmet, insulated gloves, safety belt, etc.).

Ground preview

Pre-installation check of components is carried out on the ground first;

For the combination parts (e.g. tie rod + hoop + screws), test-fit once in advance to confirm the match.

Intsallation Steps(using common fixtures as an example)

1. U-clamp and pole hoop installation

Sleeve the U-clamp into the corresponding position of the pole;Use bolts to tighten according to the design drawings, taking care not to over-tighten resulting in crushing the pole;

Washers must be placed correctly to ensure a solid structure.

2. Tie wire device installation

Install the ground anchor/anchor plate first to ensure that the burial depth and angle are compliant;Attach the pulling rod and clamp the wire with the pulling clevis;

All pulling wires shall be kept under uniform force to avoid tilting of wires.

3. Installation of Street Light Arm/Accessory Components

Determine the mounting height and angle;Securely fasten the arm and fixture connectors with bolts;

Check that the luminaire alignment avoids metal edges to prevent abrasion.

Quality Acceptance

Carry out a comprehensive inspection after the installation is completed, including the firmness of the mechanical connection, the reliability of the electrical connection, and the integrity of the anticorrosion treatment. Conduct the necessary electrical tests to ensure that the insulation and grounding effect meet the standard requirements.

Maintenance

Regular Inspections

Proper maintenance includes routine inspections, cleaning, and replacement of worn fixtures Establish a regular inspection system to check the mechanical integrity, corrosion condition, and looseness of connections of the fixtures. During the inspection process, the tower is evaluated – sometimes requiring drilling or probing – to assess its strength .

Preventive Maintenance

Remove dirt and corrosive materials from the surface of the fittings and treat exposed metal surfaces for corrosion. Periodically tighten bolted connections and replace deteriorated seals and gaskets. Inspection labels and markings provide maintenance personnel with the information necessary to help them identify poles and perform necessary repairs.

Troubleshooting

When damage or degradation of the fixture is detected, a maintenance plan should be developed immediately. For gold fixtures with impaired structural integrity, they should be replaced promptly. All maintenance operations must be carried out under power failure, and safety operating procedures should be strictly adhered to.

Regular Maintenance Recommendations

Perform inspections every 6~12 months;

Check for corrosion, deformation, looseness or breakage;

Cold spraying of zinc can be applied to the damaged parts of hot-dip galvanized layer;

There should be no trace of abnormal heating or discoloration at the contact of all wires and fittings.

Replacement Standard

Cracks, metal fatigue, inability to tighten, slipping wire, etc., should be replaced immediately.

For the Corroded or loose fittings are strictly prohibited to being use, to prevent the line hidden danger.

How to Work With us

Provide 3d drawings

Evaluate the quotation

Manufacturing

Order delivery

Get 3-day standard lead times on simple parts between 10 mm x 10 mm and 200 mm x 200 mm. Upload your part to see if it’s eligible.

Do you accept small orders?

Absolutely. Our minimum order quantity is 1 piece. You can order a small amount to feel the high quality of our products!

How long is your product warranty?

We offer a 2 years warranty on all our products

What’s your typical lead time?

Lead time depends on part complexity and order volume. For most prototypes or low-volume runs, we offer lead times as fast as 5–7 working days. Rush orders can often be accommodated.

Can I request a sample?

Yes. For Electric Power Fitting, we can provide first article samples upon request. Whether it’s sheet metal, CNC-machined, or assembled parts, we offer sample production to help you evaluate form, fit, and function before moving into full production.

Do you provide type test reports or third-party certifications (e.g., IEC, ANSI)?

Yes. We can provide type test reports and third-party certifications upon request, especially for projects requiring compliance with IEC, IEEE, or national grid standards.

Can I order a complete set for a specific tower type or substation project?

Absolutely. We support full-set procurement based on tower design or line configurations. Just send us your BOM or technical drawings.